Sledge Drive Anchor Systems

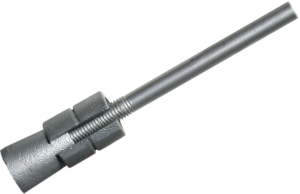

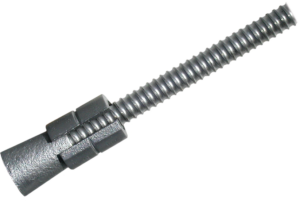

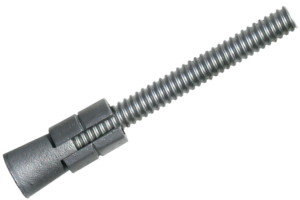

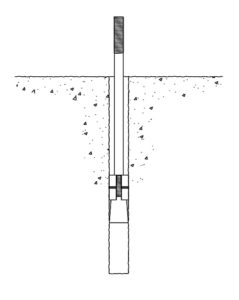

Sledge Drive Mechanical Anchors

| Steel Type |

Bar Diameter | Maximum Factored Design Load |

Ultimate Strength |

Drill Hole |

Minimum Embedment (3000 PSI – f’c) |

Minimum Embedment (6500 PSI – f’c) |

Part Number B8S Cone / Shell (B7S Cone / Shell) |

|---|---|---|---|---|---|---|---|

| B1S Smooth RodB8S All-Thread N.C. RodB7S All-Thread Coil Rod |

3/8” (10 mm) |

7.8 kips (32.7 kN) |

9.8 kips (43.6 kN) |

1-5/8” (41 mm) |

5” (127 mm) |

4” (102mm) |

R4M03RB0 / R4A13 (R4MC3RB0 / R4A13) |

| 1/2” (13 mm) |

13.5 kips (60.0 kN) |

18 kips (80.1 kN) |

1-5/8” (41 mm) |

8” (203 mm) |

6” (152 mm) |

R4M04RB0 / R4A13 (R4MC4RB0 / R4A13) |

|

| 5/8” (16 mm) |

16.8 kips (74.7 kN) |

22.5 kips (100 kN) |

1-5/8” (41 mm) |

9” (228 mm) |

7” (178 mm) |

R4M05RB0 / R4A13 (R4MC5RB0 / R4A13) |

|

| 3/4” (19 mm) |

27.0 kips (120 kN) |

36 kips (160 kN) |

1-5/8” (41 mm) |

12” (305 mm) |

9” (228 mm) |

R4M06RAC / R4A13 (R4MC6RAC / R4A13) |

|

| 7/8” (22 mm) |

43.5 kips (193 kN) |

58 kips (258 kN) |

1-5/8” (41 mm) |

16” (407 mm) |

12” (305 mm) |

R4M07RAC / R4A13 (R4MC7RAC / R4A13) |

|

| R50 Grade 60 All-Thread Rebar |

#4 – 1/2” (13 mm) |

12 kips (53.3 kN) |

16 kips (71.2 kN) |

1-5/8” (41 mm) |

8” (203 mm) |

6” (152 mm) |

R4MG4RAC / R4A13 |

| #5 – 5/8” (16 mm) |

19.2 kips (85.4 kN) |

26 kips (114 kN) |

1-5/8” (41 mm) |

10” (254 mm) |

8” (203 mm) |

R4MG5RAC / R4A13 | |

| R61 Grade 75 & Grade 80 All-Thread Rebar |

#6 – 3/4” (19 mm) |

33.0 kips (146 kN) |

44 kips (196 kN) |

1-5/8” (41 mm) |

13” (331 mm) |

10” (254 mm) |

R4MG6RAC / R4A13 |

(1) Minimum embedment depths reflect values for ductile steel failure in accordance with ACI 318 for 3000 and 6500 PSI concrete, respectively.

(2) Sledge drive anchor minimum spacing shall be the minimum embedment depth (h.ef) multiplied by 3 in accordance with ACI 318 for 3000 and 6500 PSI concrete, respectively.

(3) Sledge drive anchor minimum edge distance shall be the minimum embedment depth (h.ef) multiplied by 1.5 in accordance with ACI 318 for 3000 and 6500 PSI concrete, respectively.