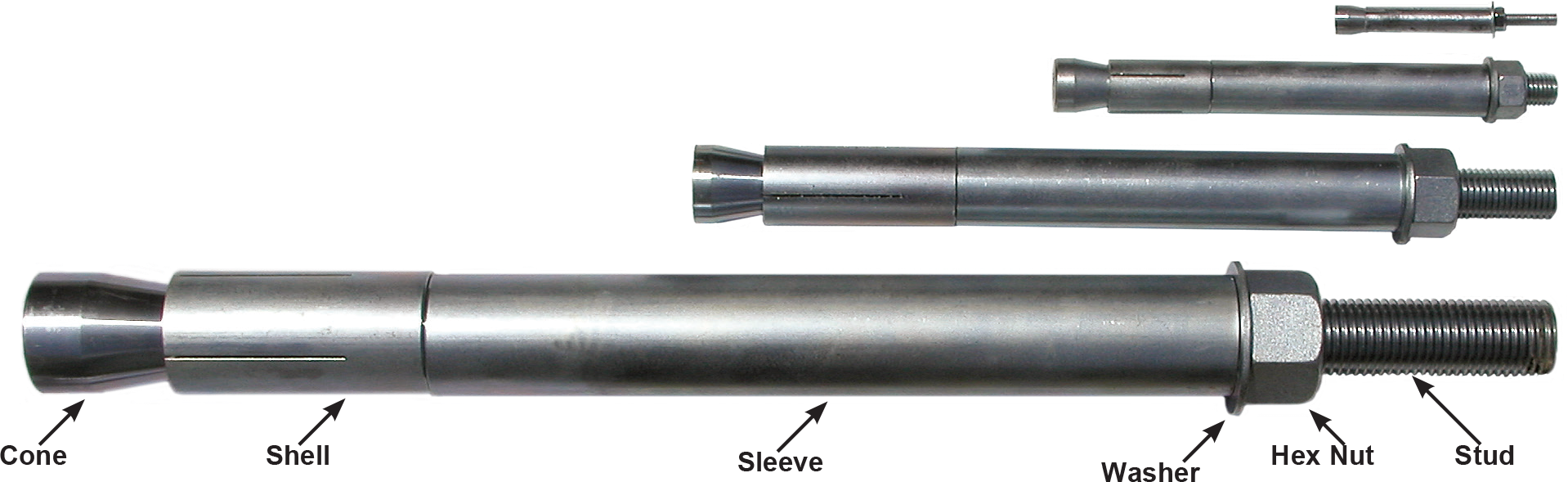

S-9 Undercut Concrete Anchor

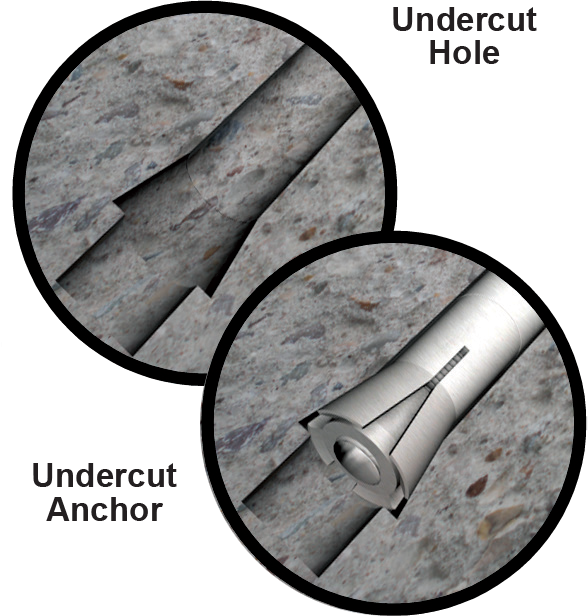

Williams S-9 Undercut Bearing Anchor was designed to eliminate the direct lateral stress found in the setting of conventional anchors and to bring its characteristics closer to those of cast-in-place anchors. Through the use of Williams undercutting tool, along with Williams undercut anchor, the conical shape of the anchor fits into the conical cut of the hole. This produces a positive expansion anchoring system that develops the tensile capacity of the bolt without slip or concrete failure. Because the anchor head is larger than the drill hole size, a properly embedded anchor will consistently develop 100% of the ASTM A193 Grade B7 bolting material.

Advantages of Williams Undercut Anchors

Cyclic Loading in Cracked Concrete

In situations where the diameter of the hole is increased due to changes caused by nature, the S-9 Undercut Bearing Anchor withstands cyclic loads in the cracked concrete member because the undercut of the hole is much larger than the top of the hole.

High Levels of Preload

Williams high strength stud bolt is threaded the total length of the bar to provide uniform stress throughout the bolt. When combined with Williams undercut head assembly the product is an anchor which will retain a much higher preload than a standard friction anchor.

Vibratory Loads

Throughout the destructive testing on Williams undercut anchor there has been consistent ductile failure on the stud bolt demonstrating a high reliability of safety. Therefore the S-9 Undercut anchor may be used safely with vibration equipment and piping.