Corrosion Protection

The level of corrosion protection for an earth anchor is primarily dependent on the service life of the anchor, the aggressivity of the environment, installation methods and consequences of failure. An anchor with a service life greater than 24 months is generally considered permanent. Permanent anchors should always have some type of corrosion protection incorporated into their design.

Ground aggressivity is generally influenced by the following:

- Electrical resistivity of the soil (Soil is aggressive if resistance is less than 2000 ohm-cm.)

- pH value of the soil (Soil is aggressive if less than 5.5)

- Chemical characteristics of the ground water, rock, or soil (salt water, slag fill, industrial waste, organic fill etc.)

- Moisture

- Presence of oxygen

- Stray electrical currents

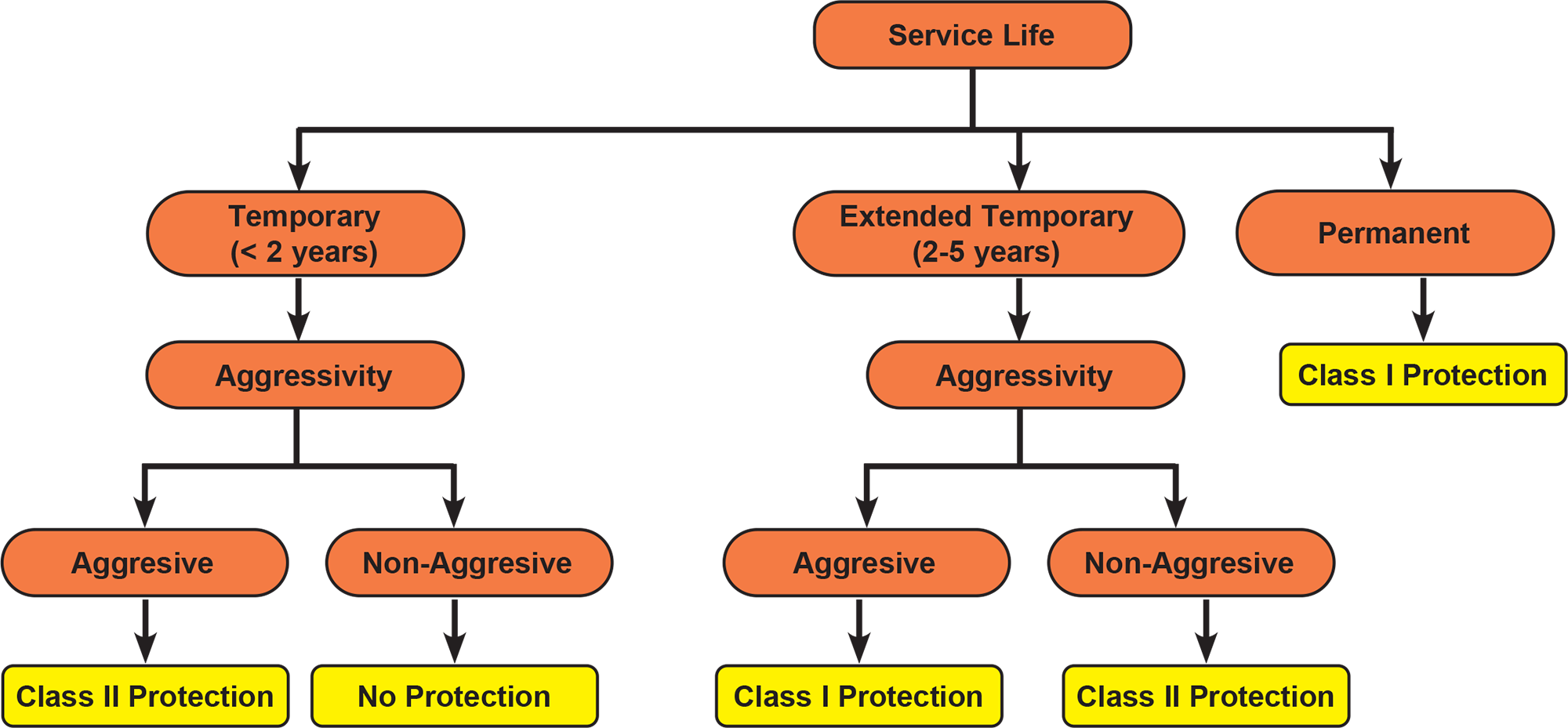

Governing Specifications for each anchor application may specify different protection schemes and these specifications should always be followed in designing the appropriate corrosion protection level. The following “Decision Tree”published in the PTI Recommendations for Prestressed Rock and Soil Anchors, assists designers in following a logical approach to corrosion protection selection:

Grout Bonded Rock or Soil Anchors

The standard permanent grout bonded rock or soil anchor consists of an epoxy coated or galvanized anchor rod, grouted in an oversized drill hole. Centralizers should be used to assure good grout cover (approximately 25 mm) around the bar. Additional corrosion protection may be desired if the rock or soil is considered to be aggressive, consequences of failure are high or anchoring into material where good grout cover is difficult to achieve. Williams Multiple CorrosionProtection (MCP) systems offer increasing barriers against corrosion attack. Williams MCP systems allow the anchor bar to be encapsulated in a pre-grouted poly-corrugated tube. Protective end caps may also be used to seal the nut and washer from the environment when the outer end of the anchorage will not be encased in concrete.

Grout Bonded Multi-Strand Anchors

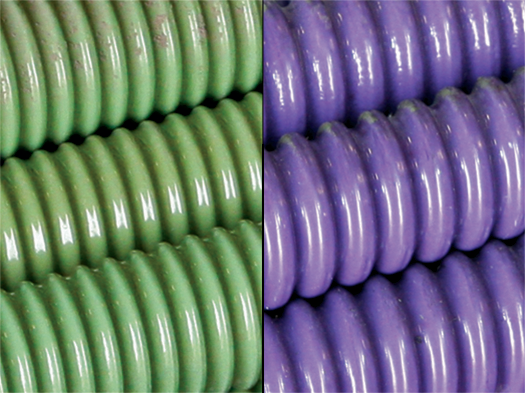

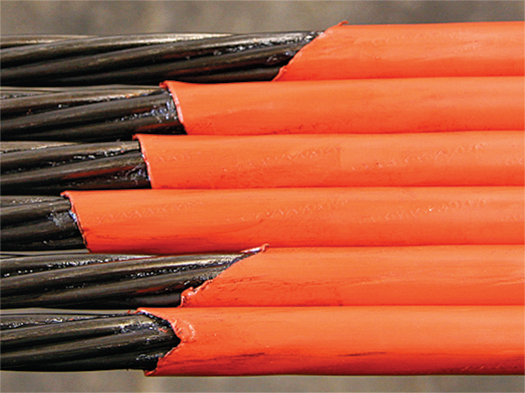

Williams also offers permanent and temporary multi-strand ground anchors. Williams strand anchors are offered with a corrosion inhibiting compound under an extruded high density polyethylene/polyproplyne in the anchor unbonded length. The permanent anchors are protected with corrugated high density polyethylene/polyproplyne (HDPE/PP) over the entire length of the anchor excluding the stressing tail. The corrugated (HDPE/PP) offers one level of corrosion protection while the field grouting operation inside the corrugated (HDPE/PP) offers an additional level of protection.Temporary anchors are not manufactured with the corrugated (HDPE/PP) over the anchor bond and unbonded lengths.

Mechanical Rock Anchors

Williams Spin-Lock mechanical rock anchors are used when anchoring into competent rock. The standard WilliamsSpin-Lock anchor relies on cement grout for corrosion protection. Williams Spin-Locks can be specified with a hollow anchor bar, allowing the system to be grouted from the lowest gravitational point in both up and down bolting applications. This provides a solid grout cover surrounding the anchor rod. Unlike the bonded rock anchor, the Spin-lock is grouted after the anchor is stressed so cracking of the grout column due to prestressing is eliminated. Spin-Lock anchors have been in service since 1959 and in most cases have relied strictly on cement grout for corrosion protection. If so desired, additional corrosion protection can be provided by step drilling a larger diameter drill hole, which provides additional grout cover, or by galvanizing the steel anchor rod. Protective end caps may also be used to seal the nut and washer from the environment when the outer end of the anchorage will not be encased in concrete.

Anchor Head Protection

The most important section of an anchor that needs adequate corrosion protection is the portion of the anchor exposed to air/oxygen. This is typically defined as the “anchor head”, which generally consists of a steel bearing plate, a hex nut and washer for a bar system, or a wedge plate and wedges for a strand system. For permanent ground anchors it is best to galvanize the hex nut and plates even if the bar is epoxy coated. Galvanized components, if scratched during shipping, are less likely to cause corrosion concerns than scratched epoxy coated components. The end of the steel bar protruding out from the hex nut is often protected by the use of a plastic or steel end cap packed with grease or cement grout. Williams offers several different types of PVC and metal end caps to provide corrosion protection at otherwise exposed anchor ends.

End Caps

Williams offers several different types of end caps to provide corrosion protection at otherwise exposed anchor ends. Most often the caps are packed with corrosion inhibiting grease. Caps made from steel are used in exposed impact areas. The Fiber Reinforced Nylon End Cap meets the Florida DOT standards for New Directions of Post-Tensioned Bridges.

Methods of Corrosion Protection

| Corrosion Protection Type | Abrasion Resistance (4=best) | Typical Thickness | Relative Cost (4=highest) | Production Lead Time | Can be applied to accessories? | Applied in the Field? |

|---|---|---|---|---|---|---|

| Hot Dip Galvanizing | 4 | 3-4 mils | 2 | 2-4 weeks | yes | no |

| Epoxy Coating | 1 | 7-12 mils | 1 | 2-3 weeks | yes | no |

| Pre-Grouted Bars | 3 | 2″, 3″ or 4″ tubing | 3 | 2 weeks | no | yes |

| Extruded Polyethylene Coating | 2 | 23-25 mils | 1 | 2-4 weeks | no | no |

| Corrosion Inhibiting Compound | 2 | N.A. | 2 | 2-4 weeks | yes | yes |

• Other thicknesses can be applied, contact a Williams representative for issues regarding threadability of fasteners

• Combination of protection methods are available (i.e. epoxy bar with a pregrout section, galvanizing with epoxy)

• Field patch kits are available for galvanized and epoxy coated products

• Field procedures are available for coupling (2) pregrouted anchors

• Contact Williams for more information regarding the appropriate corrosion protection level and corresponding governing reference specifications/documents.

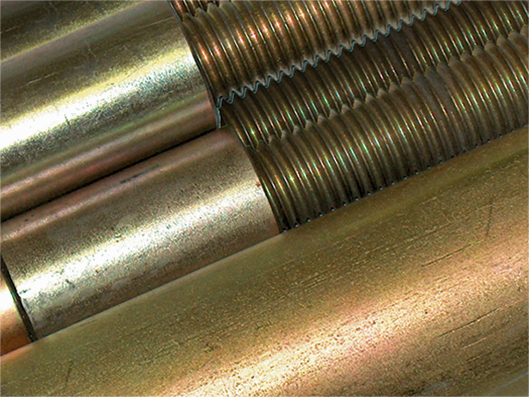

Epoxy Coating

Fusion bonded epoxy coating of steel bars to help prevent corrosion has been successfully employed in many applications because of the chemical stability of epoxy resins. Epoxy coated bars and fasteners should be done in accordance with ASTM A775 or ASTM A934. Coating thickness is generally specified between 7 to 12 mils. Epoxy coated bars and components are subject to damage if dragged on the ground or mishandled. Heavy plates and nuts are often galvanized even though the bar may be epoxy coated since they are difficult to protect against abrasion in the field. Epoxy coating patch kits are often used in the field for repairing nicked or scratched epoxy surfaces.

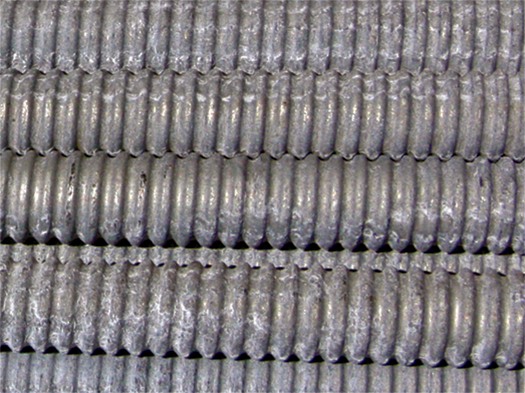

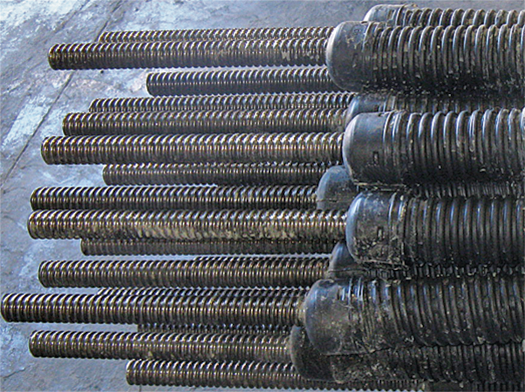

Hot Dip Galvanizing

Zinc serves as a sacrificial metal corroding preferentially to the steel. Galvanized bars have excellent bond characteristics to grout or concrete and do not require as much care in handling as epoxy coated bars. However, galvanization of anchor rods is more expensive than epoxy coating and often has greater lead time. Hot dip galvanizing bars and fasteners should be done in accordance with ASTM A153. Typical galvanized coating thickness for steel bars and components is between 3 and 4 mils. 150 KSI high strength steel bars shall require special cleaning procedures to avoid problems associated with hydrogen embrittlement in compliance with ASTM A143.

Extruded Polyethylene/Polypropylene

Williams strand tendons contain an extruded high density polyethylene/polyproplyne sheathing around each individual strand in the free-stressing portion of the anchorage. The sheathing is minimum 60 mils thick and applied once the 7-wire strand has been coated with a corrosion inhibiting compound. Extruded polyethylene/polyproplyne sheathing provides a moisture tight barrier for corrosion protection and allows the strand to elongate freely throughout the free-stressing length during the prestressing operation.

Corrosion Inhibiting Grease, Gel or Wax with Sheath

Williams corrosion inhibiting compounds can be placed in the free stressing sleeves, in the end caps, or in the trumpet areas. Often bars are greased/wax gelled and PVC is slipped over the greased/wax gelled bar prior to shipping. Each are of an organic compound with either a grease or wax gel base. They provide the appropriate polar moisture displacement and have corrosion inhibiting additives with self-healing properties. They can be pumped or applied manually. Corrosion inhibiting compounds stay permanently viscous, chemically stable and non-reactive with the prestressing steel, duct materials or grout. Both compounds meet PTI standards for Corrosion Inhibiting Coating.

Cement Grout

A contributing layer of corrosion protection for prestressed concrete anchors is complete

encapsulation in cement grout of the steel tendon from the base of the concrete anchor to the anchorage. Portland cement grouts are alkaline in nature, render encased steel into a passive state, and eliminate any contact with the steel to air or water. Intelligent design, followed by thorough grouting operations performed by trained technicians provides a competent layer of corrosion protection for Williams prestressed concrete anchors. Cement grout should not be considered a contributing means of corrosion protection if used with a passive concrete anchor application as the grout will be prone to cracking when elongation occurs due to the dynamic loading of the passive anchor.

Williams recommends a Portland cement based, shrinkage compensated, or expansive grout as the cement grout corrosion protection for prestressed concrete anchor applications. Grout should be injected after pre-stress forces are locked off by the use of grout tubes, de-air holes, or grout attachments to fill the remaining drill hole annulus around Williams concrete anchors.

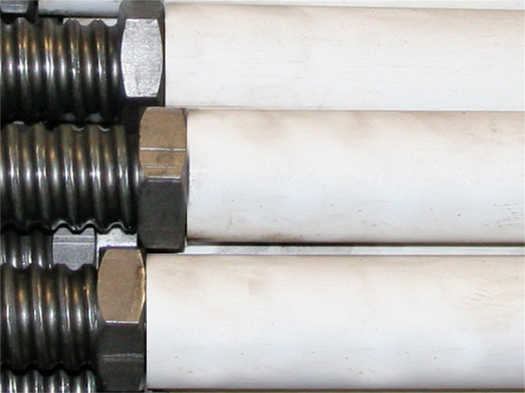

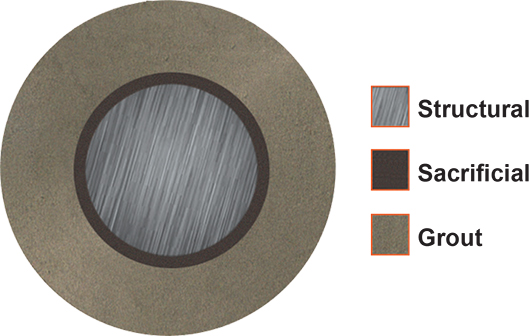

Pre-Grouted Bars

Cement Grout filled corrugated polyethylene tubing is often used to provide an additional barrier against corrosion attack in highly aggressive soils. These anchors are often referred to as MCP or Multiple Corrosion Protection anchors. The steel bars are wrapped with an internal centralizer then placed inside of the polyethylene tube where they are then factory pre-grouted. When specifying couplings with MCP ground anchors, verify coupling locations with a Williams representative.

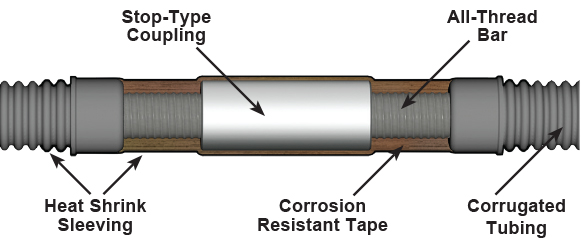

Adhesive Backed Heat Shrink

Provides a corrosion protected seal when connecting smooth or corrugated segments.

Petrolatum Tape

This is a non-woven synthetic fabric carrier, fully impregnated with a neutral petroleum-based compound. This product is stable in composition and plasticity over a wide temperature range. It is commonly applied over coupled bars in the field and is typically covered with an adhesive heat shrink sleeve or tape.

Coal Tar Epoxy

Coal tar epoxy has shown to be abrasion resistant, economical and durable. This product when specified should meet or exceed the requirements of (a) Corp of Engineers C-200,C200a and (b) AWWA C-210-92 for exterior. Typically the dry thickness is between 8 and24 mils. Make sure the surfaces of the bar are clean and dry before coating

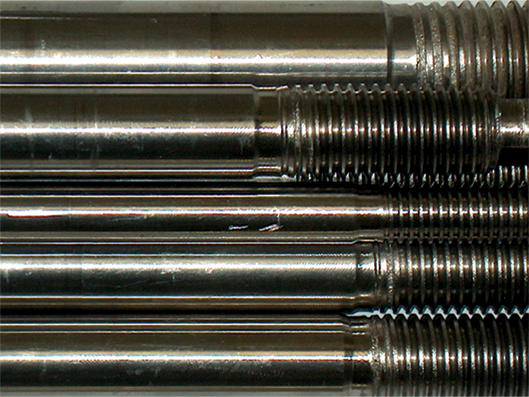

Stainless Steel

Stainless steel can be specified for use with most of Williams anchors (except for Spin-Lock mechanical anchors). Williams can supply anchor rods and components in grades of 304 and 316 for use in highly corrosive environments. Stainless steel is the best means of corrosion protection available from Williams Form Engineering, however, steel strengths are often reduced and anchor prices are increased. When specifying stainless steel make sure to specify the steel grade and make note of the change in strengths from different stainless steel grades. Some stainless steel types require longer lead times.

Electro Zinc Plating

Zinc plating is a process which deposits a thin layer of zinc over the steel. It is different from galvanizing because zinc plating is an electro-chemical process and not a dip in molten zinc. The advantages of zinc plating over galvanizing are control over zinc thickness and smoother surfaces. The zinc protects the steel as a sacrificial coating. If the coating is damaged, the sacrificial action continues as long as any zinc remains in the immediate area. Electro zinc plating should be done in accordance with ASTM B633 Type II. Commercial zinc plating is commonly 0.0001 inches to 0.0005 inches in thickness and does not require oversized tapped components.

Sacrificial Steel

Sacrificial steel as a means of corrosion protection has become widely accepted in use for soil nails and micropiles. It involves the allowance of a calculated amount of steel on the outer perimeter of the tendon to be consumed by corrosion. The area of sacrificial steel is deducted from the total cross-sectional area of the tendon when determining the required tendon size, and often results in increasing the bar diameter to the next larger size. The sizing and design life of the anchor tendons can be determined based upon Section 10.4.2 of FHWA Geocircular No. 7 or Section 4.3 of The UK Department of Transport’s TRR-380. This method of corrosion protection should only be used in known non-agressive ground conditions.

Field Splice for Bars

Continuous corrosion protection can even be accomplished for the MCP pregrouted anchors manufactured from Williams Form Engineering. To achieve the equivalent levels of corrosion protection the coupled sections of bar anchors can be wrapped in a grease impregnated tape that is further protected with heat shrink sleeving. This scheme is acceptable by most governing agencies and is specified in the PTI Recommendations for Prestresed Rock and Soil Anchors.