Prestressed Ground Anchors

The prestressing of a rock or soil anchor is done by one of two methods. The preferred and most accurate way to prestress an anchor is to use a hollow ram hydraulic jack which couples directly to the end of the anchor with a pull rod assembly. The jack frame typically bears against the steel plate while the hydraulic ram transfers a direct tension load to the anchor. When the prestress load is reached, the anchor nut is turned tightly against the anchor bearing plate, and the load from the jack is released. The anchor nut prevents the steel from relaxing back to its original length, therefore, the anchor has been prestressed. Once the anchor is put into service, additional elongation in the anchor rod only occurs if the applied load exceeds the prestress load.

The second method of prestressing is to use a torque tension method. Unlike competing products, Williams full, concentric, rolled threads allow for torque tensioning when applicable. This is accomplished by simply turning the anchor nut against the anchor bearing plate with a torque wrench. By using a “torque tension relationship” provided by Williams, the installer can correlate the torque reading to a corresponding anchor tension load. Although not as accurate as direct tensioning, it is often used for fast, economical installations in areas where hydraulic jacks would be cumbersome or difficult to utilize. Torque tensioning is recommended to be done using a high-pressure lubricant under the hex nut to resist frictional resistance.

Prestressed earth anchors are often used for resisting cyclic or dynamic loading caused by wind or fluctuating water tables. They are also used to limit or restrict structural movement due to anchor steel elongation. Common applications for prestressed earth anchors are tower foundations, tie back walls, slope and dam stability, and tunnel bolting. Non-tensioned anchors or passive dowels are often used for temporary support, resisting shear loads, static loading, or for applications with low consequences of failure.

Benefits of a Prestressed Anchor:

- Pre-Tested – By prestressing an anchor, each bolt is essentially “pre-tested”, assuring it will hold its design load prior to final construction.

- Eliminate Fatigue Stress – Fatigue failure is minimized since the service load must exceed the prestressed load of the bolt to cause additional steel elongation. Therefore, the periodic stretching and relaxing that causes fatigue failure is eliminated.

- Eliminate Uplift – Prestressing can eliminate a “floating” condition of a foundation due to the natural hydraulic pressures or uplift loads caused by wind or other overturning moments.

- Negligible Bond Stress Relief – In cases where the earth anchor free-stress length is grouted after prestress, the grout hardens around the deformations of the bar and bonds to the rock in the drill hole to help prevent stress relief in the bolt.

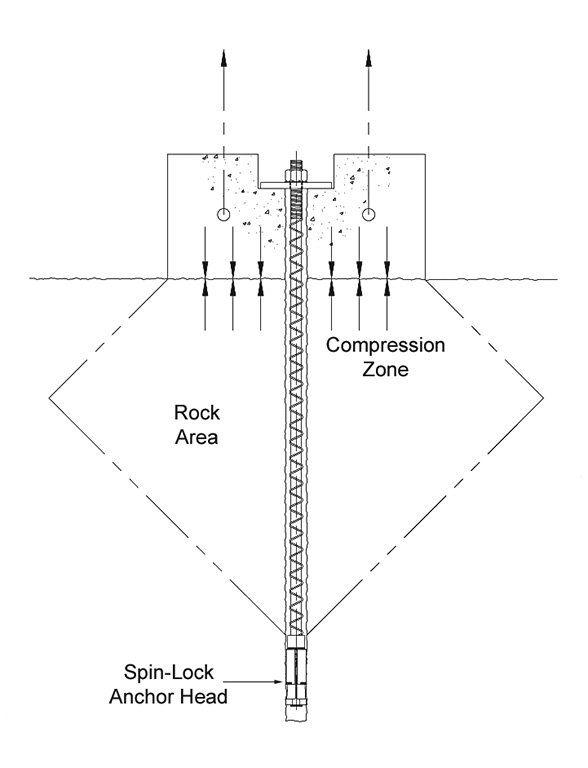

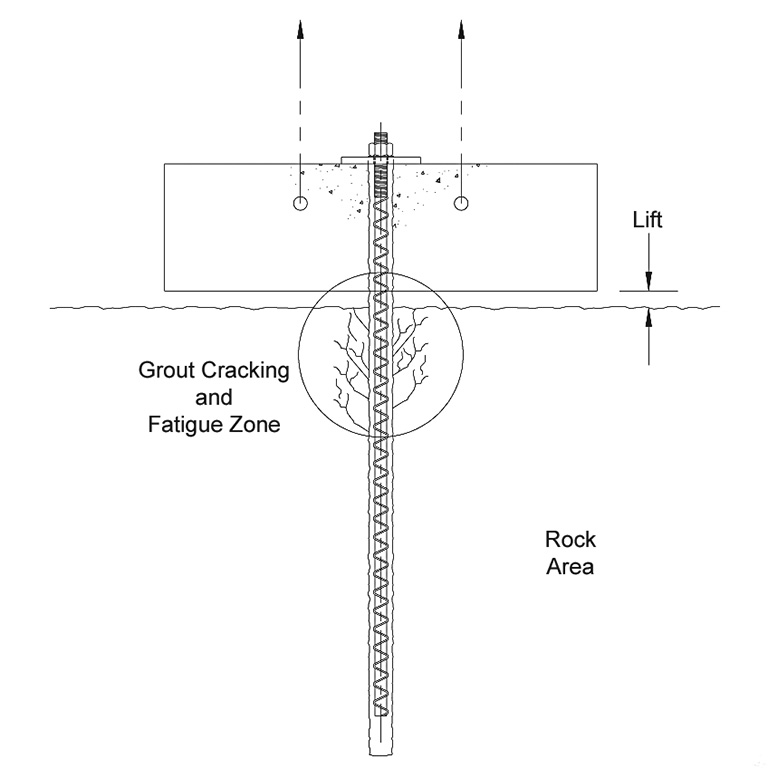

- Corrosion Protection – A prestressed earth anchor will not elongate through the grout column in the free-stressing length. Elongation breaks down and cracks the grout, opening the door to corrosion and eventual failure. This is a common problem with passive or “non-tensioned” rock dowels.

Non-Tensioned Dowels May Produce the Following Effects:

- Not Pre-Tested – Any application of load onto the bolt will cause the grout to crack in the first several inches of drill hole depth.

- Floating Condition – Allows floating of foundation or uplift of the structure due to steel elongation.

- Possible Fatigue Failure – Bolt can stretch and relax as the load varies.

- Possible Corrosion Problem – Bolt elongation will crack protective grout cover.With a non-tensioned dowel, anchorage starts at the surface and actually breaks down and cracks the grout as the load transfers deeper along the length of the bolt. Over time the total anchorage may be lost due to these recurring grout breakdowns.

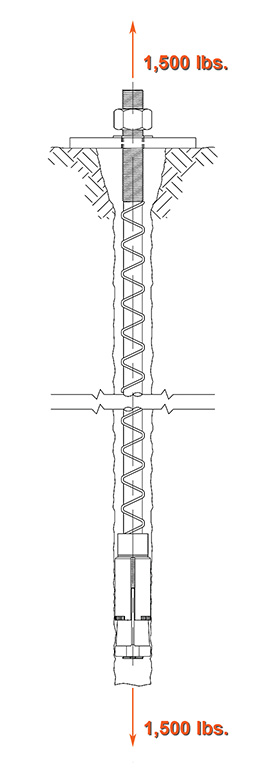

Free Body Diagrams

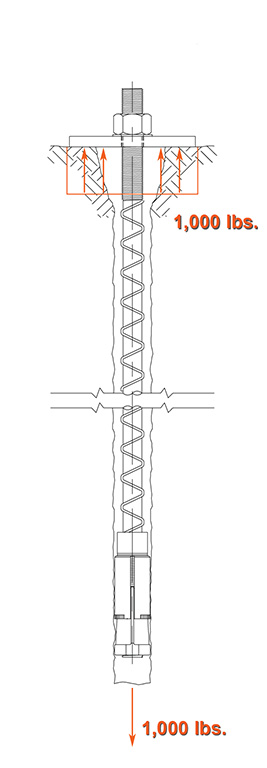

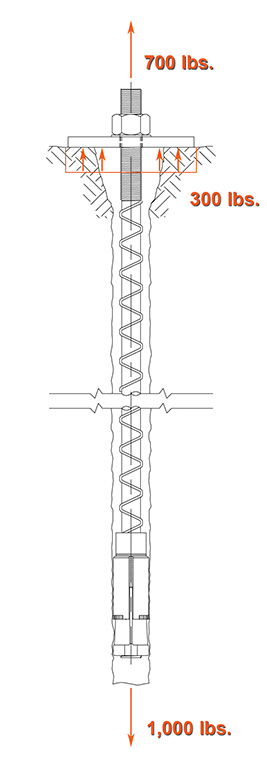

These diagrams are shown to help illustrate what happens to a prestressed anchor when an external load is applied. The external load must exceed the prestressed amount before affecting the original load.

1. Prestress load of 1000 lbs.

When a prestress load is applied and locked off, the anchorage load is equal to the force carried by the hex nut or the load bearing against the anchor plate.

2. External load of 700 lbs. is applied to the anchor

When an external force is applied to a prestressed anchor, the force on the bearing plate is reduced by the same amount as the external load. However, the anchor load is still unchanged unless the external load exceeds the prestress load.

3. External load of 1500 lbs. is applied

If the external load exceeds the prestress load, the nut is no longer holding a load. Then the anchorage load will be the same as the external load until anchor or rock/soil failure occurs.