Soil Nail System

Williams Grade 75 & Grade 80 and 150 KSI All-Thread-Bar soil nail components create an in-situ reinforcement system for the stabilization of excavations and slopes during top-down construction. Oversized holes of 4” to 10” in diameter are drilled and the centralized soil nail component is placed. The drill hole is then tremie grouted with Williams Wil-X-Cement grout. After the drill hole grout has cured, the soil nails may be torque tensioned against the protective shotcrete face to a slight load if desired.

Suggested working loads on common soil nails should not exceed 60% of the bar’s ultimate strength. In granular soils, Williams Geo-Drill Injection Anchors are often used successfully as a substitution for solid bar soil nails. Pull out capacity is a function of drill hole diameter, depth, over burden stress and the angle of internal friction of the in-situ soil. Field tests are recommended to establish necessary bond lengths. However, typical anchorages in granular soils have yielded pull out strengths of 2-10 kips per foot of embedment on lengths over 10 feet. See Grade 75 & Grade 80 All-Thread Rebar, 150 KSI All-Thread-Bar, or Geo-Drill Injection Anchor for more information.

- Rugged thread with precision fit for durability and ease of use.

- 360° of concentric thread for unmatched grout to bar bond.

- Mechanical stop-type couplers able to develop 100% of the bar’s tensile capacity for the most reliable bar to bar connections available.

- Grade 75 & Grade 80, Grade 150 KSI and Geo-Drill with full circular effective areas.

- Several options of corrosion protection including epoxy coating, galvanizing, sacrificial steel, cement grout and multiple corrosion protection for both temporary and permanent use.

- Manufacturing versatility unmatched by any soil nail supplier in North America.

- Connection abilities with structural and non-structural wall face attachments.

Stress Distribution of a Soil Nail

Unlike a prestressed rock or soil anchor, the interaction between soil nails, the facing, and the soil behind the wall is complex and causes redistributions of tensile forces at different points along the nail. The mobilized shear stress along the grout-soil interface is in general not uniform and changes in direction along the nail length at a point near the slip surface. The maximum force in the nail also occurs at this point. (Reference Report No FHWA-NHI-14-007, also known as Geocircular #7)

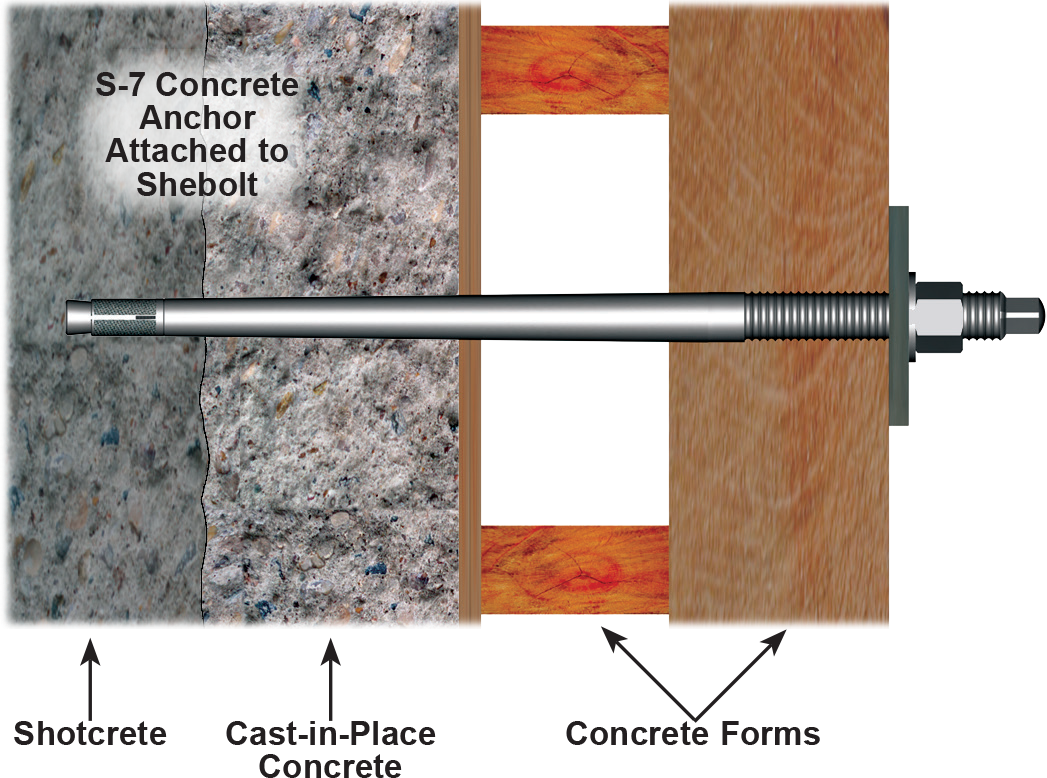

One-Sided Wall Forming

Williams offers an extensive line of concrete forming hardware that can be used in conjunction with soil nails for permanent wall forming. Williams offers she-bolts and coupling systems capable of developing 100% of the bar strength.