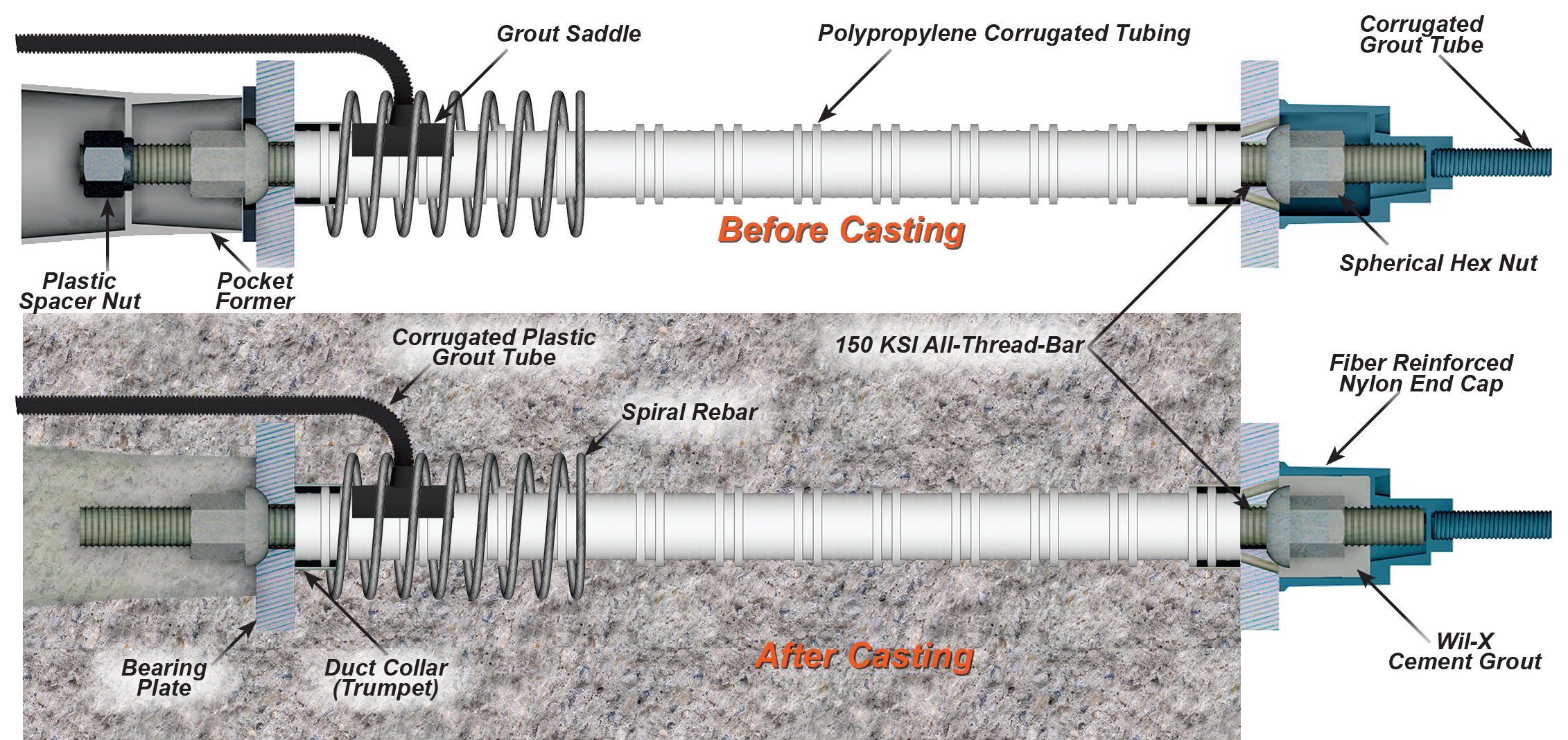

Williams Post-Tensioning System

Williams PreStressing / Post Tensioning Systems consist of high tensile steel bars available in seven diameters from 1” (26 mm) to 3” (75 mm) with guaranteed tensile strengths to 1027 kips (4568 kN). They are provided with cold-rolled threads over all or a portion of the bar’s length. All tension components for the systems are designed to develop 100% of the bar strength. All components of the systems are designed and manufactured in the United States. Williams All-Thread-Bar systems have been field-proven around the world.

Applications

Williams All-Thread-Bars were developed for use as Prestressing bars. Over the years many other applications have been adopted such as:

- Transverse Post Tensioning

- Longitudinal Post Tensioning

- Pile Test Anchors

- Rock Anchors

- Concrete Ties

- Hanger Bolts

- Jacks

- Structural Steel Frame Ties

- Shear Pins

- Bridge Retrofit Applications

- Prestressed Block and Brick Construction

- Seismic (earthquake) Restrainer Systems

- Ground Anchors and Soil Nails

- Wood Structure Post-Tension Bars

- Temporary High Strength Connections

- Tower Base Plate Anchor Bolts

- Sheet Pile Ties and Tie-backs

- High Strength Concrete Reinforcement Bars

- Multiple Corrosion Protection Anchors

- Wind Generator Foundation Anchor Bolts

Placing Bars

Williams All-Thread-Bars can be placed prior to the concrete pour or assembled through ducting in cast concrete.Care should be taken not to impact the bars or subject them to excessive bending. When coupled bars are used in precast concrete, upset ducting may be used on one end when casting the concrete to allow the coupled bar to slide into place. Stop-type couplings are provided with Williams All-Thread-Bars to assure proper engagement of each bar. As a safety measure, it is always a good idea to mark the end of each All-Thread-Bar to be coupled with the proper engagement length. A grease pencil or similar tool can be used