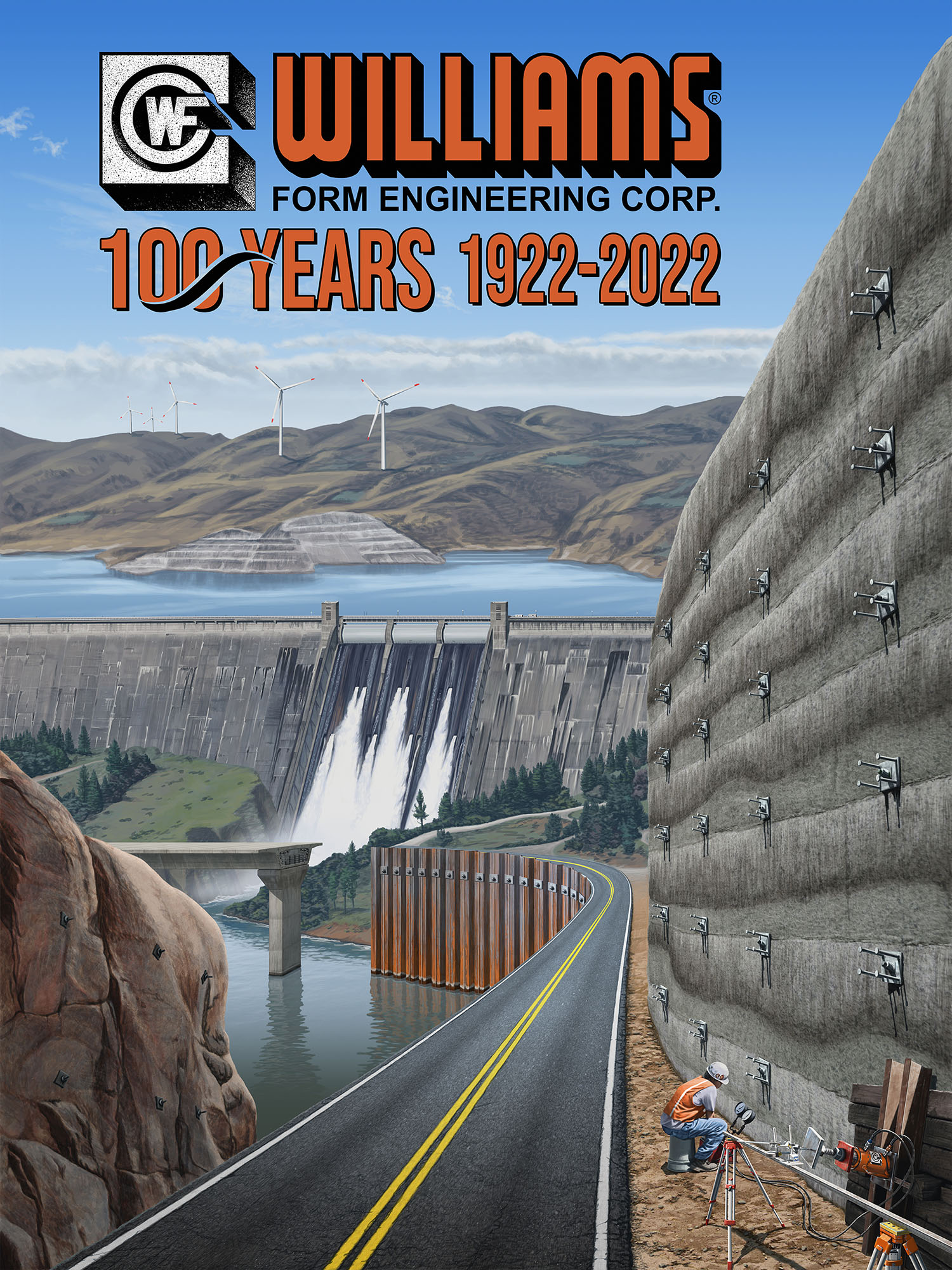

Williams Form Engineering Corporation, a family owned American company, was founded in 1922. WFEC has evolved over the decades, becoming the most trusted name in the geotechnical support industry!

Learn More

With eight locations throughout the US and Canada, Williams is well positioned to service the North American market and beyond. We put a strong emphasis on our outstanding customer service, and take pride in our ability to adapt and accommodate our customers. The majority of our high-quality products are designed and manufactured in the United States and are always offered at competitive market pricing. Williams’ product lines are supported by Williams’ Engineering Department; engineered shop drawings, calculations, installation and testing equipment, and on-site Technical Assistance is available upon request.

The success of your project is important to us! Trust Williams Form Engineering on your next project to ensure a successful outcome!

Featured Solutions

Tieback Anchors

Bonded deep into the ground using cementitious grout, these anchors transfer necessary forces to resists walls from overturning, water tanks from uplift, towers from uplift, dams from rotating and other naturally or phenomenally occurring forces applied to structures.

Learn More

Micropiles

High capacity, small diameter, drilled and grouted in-place piles designed with steel reinforcement to primarily resist structural loading. Ideal for underpinning and foundations in urbanized areas or in locations with low headroom and restricted access.

Learn More

Wind Turbine Foundations

Since the late 1990’s the wind power industry has relied on Williams’ advanced engineered anchor bolts and components to maintain the strict tolerances and ensure the highest product standards. Each wind tower supported by a Williams foundation anchor system can be relied upon to perform flawlessly throughout the life of the turbine.

Learn MoreFeatured Projects

Revolutionizing Rebar Cage Construction

Historically, rebar cages have been tied at intersections of longitudinal and transverse reinforcement with tie wire. However, engineering knowledge of the stress levels within tie wire as cages are hoisted to the upright position is virtually unknown. Rebar cage fabricators have used methods of tying that have worked on past projects, but as cages get larger, so many variables can increase the chances of failure of the cage during this critical step creating a very real safety concern. Williams Form Engineering Corporation can now offer help with this problem. Rather than using only the traditional tie wire, Williams Form now makes a much more robust connection for use at critical rebar intersections. Consisting of two high-strength steel U-Bolts with threaded ends, connected with 2 plates, these relatively low-cost connectors have been shown to significantly increase the cage stability and safety.

Telluride, CO - Mays Construction

Gorgeous Telluride, CO continues to see growth in tourism including visitors flying right into Telluride’s beautiful airport, the highest commercial airport in America! In an effort to accommodate more air traffic they are building a new, much larger hangar. Thanks to Mays Construction Specialties who is installing T40 micropiles for this structure. We appreciate the business!

Micropiles