Spin-Lock Concrete Anchors

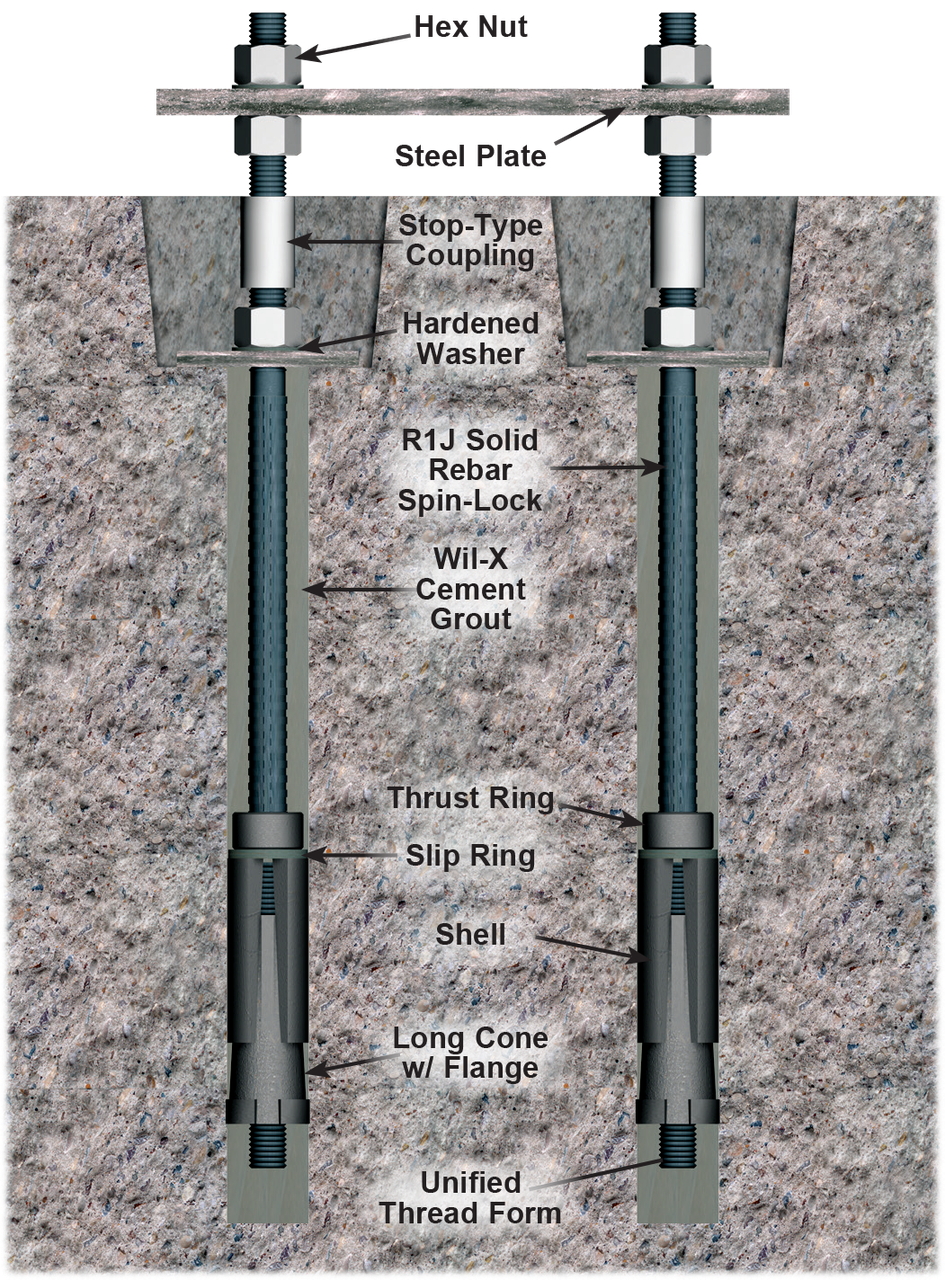

Williams Spin-Lock anchors were first used in the 1950s for rock/roof bolting in projects such as NORAD and Australia’s Snowy Mountain Power Facility. Since then many engineers, contractors, and owners have recognized the advantages of the Spin-Lock anchor system as a high capacity concrete anchor. Spin-Locks have been used successfully on rocket launch pads, nuclear power plants, large dams and spillways, tower anchors, roller coasters and several other applications requiring high capacity and dynamic load resistant concrete anchor systems. Williams Spin-Lock anchors provide the advantages of immediate anchorage, prestressing/post-tension abilities, anchorage redundancy (mechanical anchorage with a grout bond), custom manufacturing, and the highest capacities of any production mechanical anchor available today.

To comply with the need for anchors which can be used in a variety of applications with a wide range of loading capabilities…Williams has developed a complete family of concrete anchor bolts with a simple and efficient system of installation. Williams also offers a line of rental equipment for installing, testing and grouting of Spin-Lock high capacity concrete anchors.

Before proceeding with your next project, consult with a design agency familiar with Williams anchor systems, or contact your nearest Williams representative. Williams would be pleased to recommend an ideal system to meet the needs of your next application.

Spin Lock Advantages

- The mechanical head allows for a prestressed anchor which prevents anchor fatigue failure in cyclic or dynamic loading applications.

- Anchors can be custom manufactured or mechanically coupled to any length.

- Each anchor is tested to the desired working load.

- Anchors can be grouted providing redundant anchorage, corrosion protection and the grout helps to lock in prestress values.

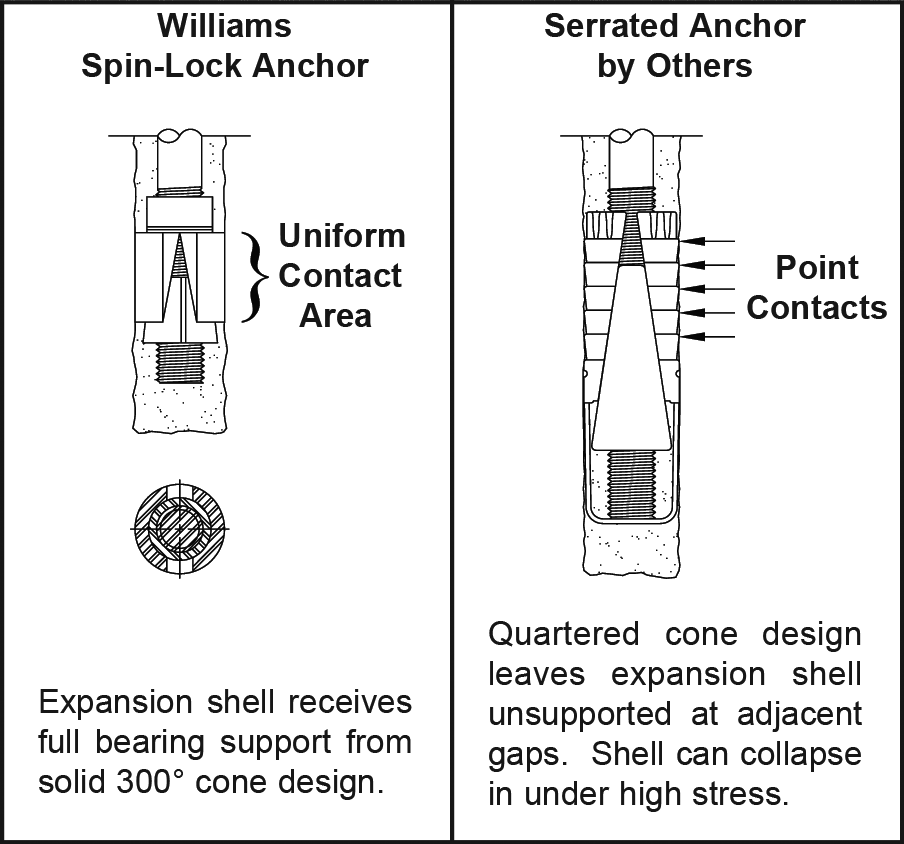

- The mechanical head provides a full 300° bearing area and opens parallel to the drill hole, avoiding point loading.

- Anchors can be designed continuously threaded for field adaptation

- Williams has testing equipment and personnel that can work with an engineer for designs with unique applications, locations or patterns.

- A selection of anchor bars is available to fit nearly every design.

- Williams Form can recommend several installation contractors in the area of the anchor installation.

- High degree of dependability allows a factor of safety in accordance with ACI 318.

- The Spin-Lock has been used in construction for over 50 years.

Prestressed Anchors for Tower or Column Supports

For several decades Engineers have based their Spin-Lock designs on the 45° cone method that was presented in ACI 349 Appendix B (1985). With recent changes in theACI publication relating to concrete anchors in ACI 318-14:Anchoring to Concrete, a standardized method of analyzing concrete anchors has been established. This is the recommended method of analyzing anchor capacities, embedment depths, concrete breakout capacities and more for tension, shear, and combined loading scenarios.

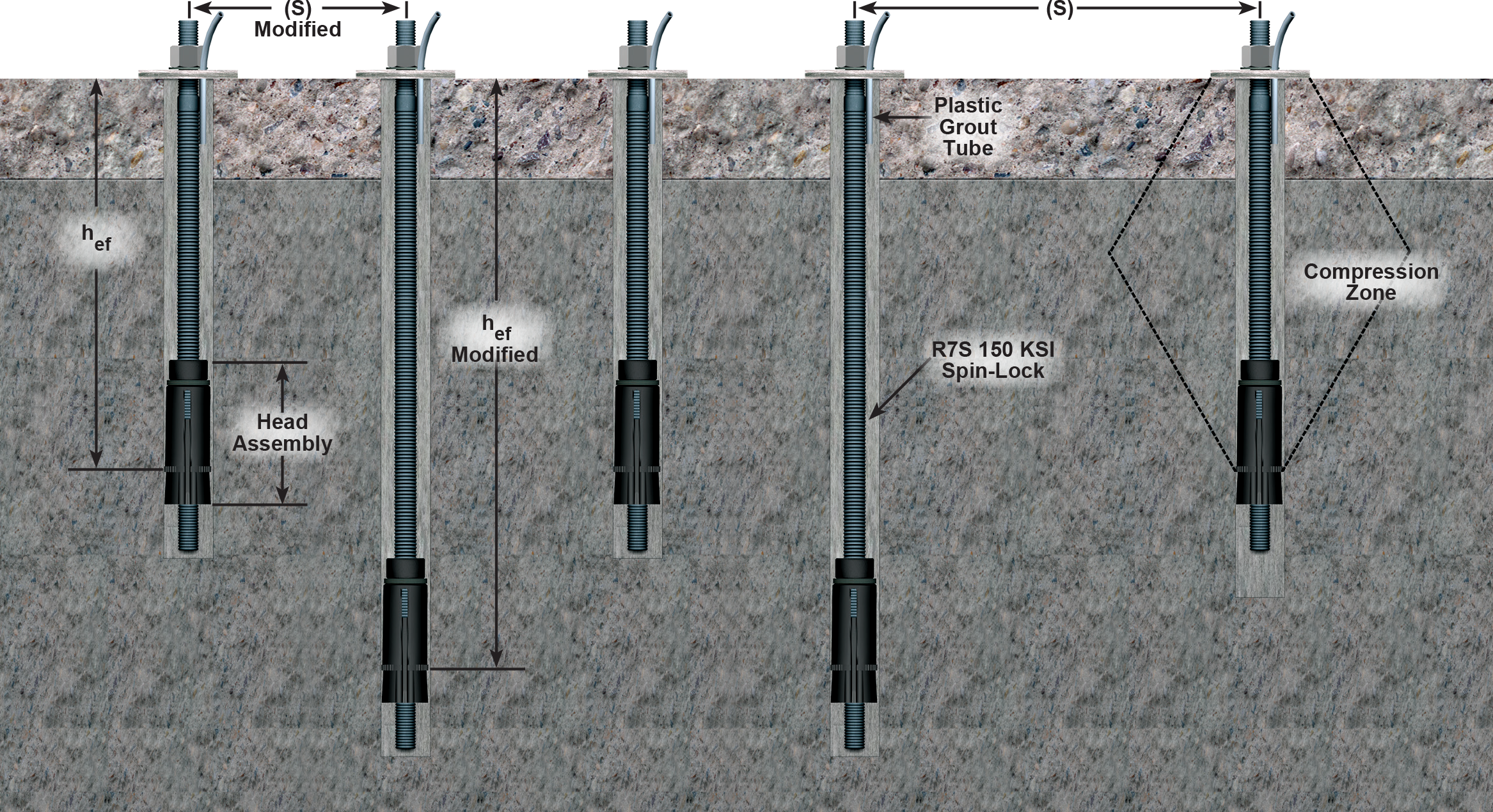

At times, job conditions may dictate the necessity to place adjacent anchors closer than the minimum spacing (S) shown in the following table. When reduced spacing is desired it is then recommended to install the anchors by staggering thee mbedment depths or by installing the anchors at equivalent depths while ensuring confining pressures are placed on either side of a single anchor before stressing the anchors.This is accomplished by setting the mechanical head on the anchors on either side of the anchor being prestressed. When staggering the anchors, adjacent anchors should be staggered as shown in the illustration below. After the deepest anchors have been drilled, installed, grouted, and the grout has cured; adjacent anchors can be drilled and installed. This procedure would allow for (S) values to be reduced by half without the danger of fracture between holes during installation.

The ideal spacing is large enough to prevent blow out from anchor hole to anchor hole, and to develop the full combined anchor capacities. Based on the 35° cone method in ACI318, the center to center spacing to develop the full shear cone should be 3 times the recommended embedment depth.Closely spaced anchors can be designed with a deeper embedment than what is is listed in order to develop the combined anchor capacities.

For best results Williams Spin-Lock anchors should be used in high strength reinforced concrete.

Prestressing New Concrete to Old Concrete