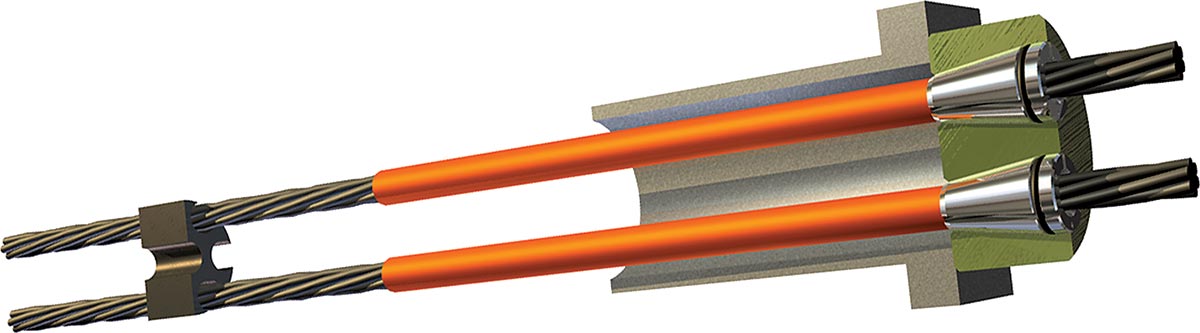

Strand Anchor System

Williams Strand Anchors utilize a high density extruded polyethylene sheath over corrosion inhibiting compound in the unbonded zone. Williams has the most technologically advanced extrusion equipment for the manufacture of permanent and temporary anchors. The state of the art equipment allows for precise extruded lengths in the unbonded zone and high quality manufacturing.

Williams Strand Anchors are typically produced from 0.6” diameter, 7 wire strand (fpu = 270 ksi, 1862 N/mm2) meeting ASTM A416 and are manufactured in accordance with the Post-Tensioning Institute’s Recommendations for Prestressed Rock and Soil Anchors.

Applications

- Dam Tie-Downs

- Temporary Excavation Support

- Landslide Mitigation

- Permanent Tieback Systems

- Slope Surface Stabilization

- Foundations

Advantages of Williams Grout Bonded Strand Anchors

- High capacity – Anchors utilize a 0.6” dia. 270 KSI (ultimate stress) strand. The number of strands per anchor dictate the load carrying capacity of the anchor.

- Lightweight – For a Class I protected anchor, the corrugated duct is grouted in the field, greatly reducing the weight of the anchor. There is more load carrying capacity per pound of 7-wire 270 KSI strand than solid bar.

- Anchors arrive to the jobsite fully fabricated and packaged in coils to allow for installation in areas where there are clearance issues or bench width constraints.

- Unlike bar systems, strand can be produced in any length.

- All Williams strand anchors utilize a small diameter greased filled extruded high density polyethylene sheathing, allowing for a greater number of individual strands to be contained in a given drill hole size. Manual greasing and sheathing of individual strands require a larger free stressing sheath.

- Stringent quality control of manufacturing is maintained because Williams’ engineering department provides shop drawings for each production order showing customer preference details and specific contract requirements.

Corrosion Protection

The anchor system can be produced to meet the Post-Tensioning Institute’s Recommendations for Prestressed Rock and Soil Anchors. Williams Strand Anchors are supplied with the following classes of Corrosion Protection:

PTI Class I – Encapsulated Tendon:

Anchorage: Wedge Plate, Bearing Plate w/ Trumpet and End Cap (where exposed).

Free Stressing Length: Corrosion inhibiting compound filled HDPE/PP sheath encased in grout filled corrugated sheathing.

Bond Length: Grout filled encapsulated corrugated sheathing.

PTI Class II – Grout Protected:

Anchorage: Wedge Plate, Bearing Plate w/ optional Trumpet and optional End Cap (where exposed).

Free Stressing Length: Corrosion inhibiting compound filled HDPE/PP sheath surrounded by external grout.

Bond Length: Bare strands, grout encased.

Design and Construction Support

Williams is committed to assisting designers and foundation engineers with prebid product information, budget pricing and anchor details. Williams’ technical staff will work with designers to ensure that the specified strand anchor system is economical and appropriate for the application.

Williams is also committed to assisting the contractor with project pricing, bearing plate calculations, quantity take-offs, anchor submittals and shop drawings. Williams’ manufacturing personnel will work with the technical staff to ensure the anchors are delivered to the jobsite, ready to install and on time. Williams also offers on-site technical assistance to the contractor.