Grade 60 Threaded Rebar

Our R6J Grade 60 Rebar is most often used in resin bolting or for anchor dowels. Depending on the application it may be more economical than Williams R61 Grade 75 All-Thread Rebar, however, the installer does not have the flexibility of a continuous workable thread. Williams offers threaded end rebar in the following sizes.

| Bar Designation Nominal Diameter & Pitch |

Minimum Net Area Thru Threads |

Minimum Ultimate Strength |

Minimum Yield Strength |

Nominal Weight |

Approx. Thread Major Dia. |

Part Number |

|---|---|---|---|---|---|---|

| #4 – 1/2” – 13 UNC (13 mm) |

0.142 in2 (91.6 mm2) |

13.3 kips (50.5 kN) |

8.52 kips (37.9 kN) |

0.67 lbs/ft (1.0 kg/m) |

1/2” (13 mm) |

R6J-04 |

| #5 – 5/8” – 11 UNC (16 mm) |

0.226 in2 (146 mm2) |

18.1 kips (80.4 kN) |

13.6 kips (60.3 kN) |

1.0 lbs/ft (1.6 kg/m) |

5/8” (16 mm) |

R6J-05 |

| #6 – 3/4” – 10 UNC (19 mm) |

0.334 in2 (216 mm2) |

26.7 kips (119 kN) |

20.0 kips (89.1 kN) |

1.5 lbs/ft (2.2 kg/m) |

3/4” (19 mm) |

R6J-06 |

| #7 – 7/8” – 9 UNC (22 mm) |

0.462 in2 (298 mm2) |

37.0 kips (164 kN) |

27.7 kips (123 kN) |

2.0 lbs/ft (3.0 kg/m) |

7/8” (22 mm) |

R6J-07 |

| #8 – 1” – 8 UNC (25 mm) |

0.606 in2 (391 mm2) |

48.5 kips (216 kN) |

36.4 kips (162 kN) |

2.7 lbs/ft (4.0 kg/m) |

1” (25 mm) |

R6J-08 |

| #9 – 1-1/8” – 7 UNC (29 mm) |

0.763 in2 (492 mm2) |

61.0 kips (271 kN) |

45.8 kips (200 kN) |

3.4 lbs/ft (5.1 kg/m) |

1-1/8” (29 mm) |

R6J-09 |

| #10 – 1-1/4” – 7 UNC (32 mm) |

0.969 in2 (625 mm2) |

77.5 kips (345 kN) |

58.1 kips (259 kN) |

4.3 lbs/ft (6.4 kg/m) |

1-1/4” (32 mm) |

R6J-10 |

| #11 – 1-3/8” – 8 UN (36 mm) |

1.23 in2 (794 mm2) |

98.6 kips (439 kN) |

73.8 kips (328 kN) |

5.3 lbs/ft (7.9 kg/m) |

1-3/8” (35 mm) |

R6J-11 |

| #14 – 1-3/4” – 5 UNC (43 mm) |

1.90 in2 (1226 mm2) |

149 kips (663 kN) |

110 kips (489 kN) |

7.7 lbs/ft (11.4 kg/m) |

1-3/4” (45 mm) |

R6J-14 |

| #18 – 2-1/4”- 4-1/2 UNC (57 mm) |

3.25 in2 (2097 mm2) |

255 kips (1134 kN) |

189 kips (841 kN) |

13.6 lbs/ft (20.2 kg/m) |

2-1/4” (57 mm) |

R6J-18 |

Structural Properties

| Diameter Range |

Yield Stress |

Ultimate Stress |

Elongation in 8″ |

|---|---|---|---|

| 1/2” to 1” (13 to 25 mm) |

60 KSI (413 MPa) |

80 KSI (552 MPa) |

7% min |

| 1-1/8” and up (29 mm) |

60 KSI (413 MPa) |

80 KSI (552 MPa) |

9% min |

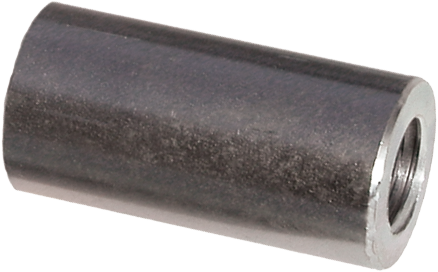

C2T Stop-Type Couplings & C2D Flange Couplings

| Bar Diameter |

Outside Diameter |

Overall Length |

Stop-Type Part Number |

Flange Coupling | |

|---|---|---|---|---|---|

| Flange Size | Part Number | ||||

| #4 – 1/2” (13 mm) |

3/4” (19 mm) |

1-1/2” (38 mm) |

C2T-04 | 2” x 2” (51 x 51 mm) |

C2D-04 |

| #5 – 5/8” (16 mm) |

1” (25 mm) |

1-3/4” (45 mm) |

C2T-05 | 2” x 2” (51 x 51 mm) |

C2D-05 |

| #6 – 3/4” (19 mm) |

1-1/8” (29 mm) |

2” (51 mm) |

C2T-06 | 2” x 2” (51 x 51 mm) |

C2D-06 |

| #7 – 7/8” (22 mm) |

1-1/4” (32 mm) |

2-1/4” (57 mm) |

C2T-07 | 3” x 3” (76 x 76 mm) |

C2D-07 |

| #8 – 1” (25 mm) |

1-1/2” (38 mm) |

3” (76 mm) |

C2T-08 | 3” x 3” (76 x 76 mm) |

C2D-08 |

| #9 – 1-1/8” (29 mm) |

1-5/8” (41 mm) |

3-1/2” (89 mm) |

C2T-09 | 3” x 3” (76 x 76 mm) |

C2D-09 |

| #10 – 1-1/4” (32 mm) |

1-7/8” (48 mm) |

3-3/4” (95 mm) |

C2T-10 | 3” x 3” (76 x 76 mm) |

C2D-10 |

| #11 – 1-3/8” (35 mm) |

2-1/8” (54 mm) |

4” (102 mm) |

C2T-11 | 3” x 3” (76 x 76 mm) |

C2D-11 |

| #14 – 1-3/4” (45 mm) |

2-1/2” (64 mm) |

5-1/2” (140 mm) |

C2T-14 | 4” x 4” (102 x 102 mm) |

C2D-14 |

| #18 – 2-1/4” (57 mm) |

3-1/2” (89 mm) |

8” (203 mm) |

C2T-18 | – | – |

H1F Heavy Duty Hex Nuts

| Bar Diameter |

Across Flats |

Across Corners |

Thickness | Part Number |

|---|---|---|---|---|

| #4 – 1/2” (13 mm) |

7/8” (22 mm) |

1.0” (26 mm) |

31/64” (12 mm) |

H1F-04 |

| #5 – 5/8” (16 mm) |

1-1/16” (27 mm) |

1.2” (31 mm) |

39/64” (16 mm) |

H1F-05 |

| #6 – 3/4” (19 mm) |

1-1/4” (32 mm) |

1.4” (37 mm) |

47/64” (19 mm) |

H1F-06 |

| #7 – 7/8” (22 mm) |

1-7/16” (37 mm) |

1.7” (42 mm) |

55/64” (22 mm) |

H1F-07 |

| #8 – 1” (25 mm) |

1-5/8” (41 mm) |

1.9” (48 mm) |

63/64” (25 mm) |

H1F-08 |

| #9 – 1-1/8” (29 mm) |

1-13/16” (46 mm) |

2.1” (53 mm) |

1-7/64” (28 mm) |

H1F-09 |

| #10 – 1-1/4” (32 mm) |

2” (51 mm) |

2.3” (59 mm) |

1-7/32” (31 mm) |

H1F-10 |

| #11 – 1-3/8” (36 mm) |

2-3/16” (56 mm) |

2.5” (64 mm) |

1-11/32” (34 mm) |

H1F-11 |

| #14 – 1-3/4” (43 mm) |

2-3/4” (70 mm) |

3.18” (81 mm) |

1-23/32” (44 mm) |

H1F-14 |

| #18 – 2-1/4” (57 mm) |

3-1/2” (89 mm) |

4.0” (103 mm) |

2-1/4” (57 mm) |

H1F-18 |

R9F Hardened Washers

| Bar Diameter |

Outside Diameter |

Inside Diameter |

Thickness | Part Number |

|---|---|---|---|---|

| #4 – 1/2” (13 mm) |

1-1/16” (27 mm) |

17/32” (14 mm) |

9/64” (3.56 mm) |

R9F-04-436 |

| #5 – 5/8” (16 mm) |

1-5/16” (33 mm) |

11/16” (17 mm) |

9/64” (3.6 mm) |

R9F-05-436 |

| #6 – 3/4” (19 mm) |

1-7/16” (37 mm) |

13/16” (21 mm) |

9/64” (3.6 mm) |

R9F-06-436 |

| #7 – 7/8” (22 mm) |

1-3/4” (45 mm) |

15/16” (24 mm) |

5/32” (4 mm) |

R9F-07-436 |

| #8 – 1” (25 mm) |

2” (51 mm) |

1-1/16” (29 mm) |

5/32” (4 mm) |

R9F-08-436 |

| #9 – 1-1/8” (29 mm) |

2-1/4” (57 mm) |

1-3/16” (30 mm) |

5/32” (4 mm) |

R9F-09-436 |

| #10 – 1-1/4” (32 mm) |

2-1/2” (64 mm) |

1-3/8” (35 mm) |

5/32” (4 mm) |

R9F-10-436 |

| #11 – 1-3/8” (36 mm) |

2-3/4” (70 mm) |

1-1/2” (38 mm) |

5/32” (4 mm) |

R9F-11-436 |

| #14 – 1-3/4” (43 mm) |

3-3/8” (86 mm) |

1-7/8” (48 mm) |

7/32” (5.6 mm) |

R9F-14-436 |

| #18 – 2-1/4” (57 mm) |

4” (102 mm) |

2-3/8” (60 mm) |

9/32” (7 mm) |

R9F-18-436 |

R8M Beveled Washers

| Bar Diameter |

Degree of Bevel |

Outside Diameter |

Inside Diameter |

Maximum Thickness |

Minimum Thickness |

Part Number |

|---|---|---|---|---|---|---|

| #4 – 1/2” (13 mm) |

14° | 1-1/4” (32 mm) |

9/16” (14 mm) |

7/16” (11 mm) |

1/8” (3 mm) |

R8M-04 |

| #5 – 5/8” (16 mm) |

11° | 1-9/16” (40 mm) |

13/16” (21 mm) |

1/2” (13 mm) |

3/16” (5 mm) |

R8M-06 |

| #6 – 3/4” (19 mm) |

11° | 1-9/16” (40 mm) |

13/16” (21 mm) |

1/2” (13 mm) |

3/16” (5 mm) |

R8M-06 |

| #7 – 7/8” (22 mm) |

15° | 2-1/16” (52 mm) |

1” (25 mm) |

3/4” (19 mm) |

1/4” (6 mm) |

R8M-08S |

| #8 – 1” (25 mm) |

15° | 2-1/16” (52 mm) |

1” (25 mm) |

3/4” (19 mm) |

1/4” (6 mm) |

R8M-08S |

| #9 – 1-1/8” (29 mm) |

15° | 2-13/16” (71 mm) |

1-5/16” (33 mm) |

1” (25 mm) |

5/16” (8 mm) |

R8M-09S |

| #10 – 1-1/4” (32 mm) |

15° | 3-3/8” (86 mm) |

1-9/16” (40mm) |

1-15/64” (31 mm) |

3/8” (9.5 mm) |

R8M-12S |

| #11 – 1-3/8” (36 mm) |

15° | 3-3/8” (86 mm) |

1-9/16” (40 mm) |

1-15/64” (31 mm) |

3/8” (9.5 mm) |

R8M-12S |

| #14 – 1-3/4” (43 mm) |

5° | 3-9/16” (91 mm) |

2-1/16” (52 mm) |

13/16” (21 mm) |

1/2” (13 mm) |

R8M-16 |

To achieve full strength of the system, beveled washers must be used in conjunction with a hardened washer.