Grade 75 & Grade 80 All-Thread Rebar

| Bar Designation Nominal Diameter & Pitch |

Minimum Net Area Thru Threads |

Minimum Ultimate Strength |

Grade 75 Minimum Yield Strength |

Grade 80 Minimum Yield Strength |

Nominal Weight |

Approximate Thread Major Diameter |

Part Number |

|---|---|---|---|---|---|---|---|

| #6 – 3/4” – 5 (19 mm) |

0.44 in2 (284 mm2) |

44 kips (196 kN) |

33 kips (147 kN) |

35 kips (156 kN) |

1.5 lbs/ft (2.4 kg/m) |

7/8” (22 mm) |

R61-06 |

| #7 – 7/8” – 5 (22 mm) |

0.60 in2 (387 mm2) |

60 kips (267 kN) |

45 kips (200 kN) |

48 kips (214 kN) |

2.0 lbs/ft (3.0 kg/m) |

1” (25 mm) |

R61-07 |

| #8 – 1” – 3-1/2 (25 mm) |

0.79 in2 (510 mm2) |

79 kips (351 kN) |

59 kips (264 kN) |

63 kips (280 kN) |

2.7 lbs/ft (3.9 kg/m) |

1-1/8” (29 mm) |

R61-08 |

| #9 – 1-1/8” – 3-1/2 (29 mm) |

1.00 in2 (645 mm2) |

100 kips (445 kN) |

75 kips (334 kN) |

80 kips (356 kN) |

3.4 lbs/ft (5.1 kg/m) |

1-1/4” (32 mm) |

R61-09 |

| #10 – 1-1/4” – 3 (32 mm) |

1.27 in2 (819 mm2) |

127 kips (565 kN) |

95 kips (424 kN) |

102 kips (454 kN) |

4.3 lbs/ft (5.5 kg/m) |

1-3/8” (35 mm) |

R61-10 |

| #11 – 1-3/8” – 3 (36 mm) |

1.56 in2 (1006 mm2) |

156 kips (694 kN) |

117 kips (521 kN) |

125 kips (556 kN) |

5.3 lbs/ft (7.9 kg/m) |

1-1/2” (38 mm) |

R61-11 |

| #14 – 1-3/4” – 3 (43 mm) |

2.25 in2 (1452 mm2) |

225 kips (1001 kN) |

169 kips (750 kN) |

180 kips (801 kN) |

7.65 lbs/ft (11.8 kg/m) |

1-7/8” (48 mm) |

R61-14 |

| #18 – 2-1/4” – 3 (57 mm) |

4.00 in2 (2581 mm2) |

400 kips (1780 kN) |

300 kips (1335 kN) |

320 kips (1423 kN) |

13.6 lbs/ft (19.6 kg/m) |

2-7/16” (62 mm) |

R61-18 |

| #20 – 2-1/2” – 2-3/4 (64 mm) |

4.91 in2 (3168 mm2) |

491 kips (2184 kN) |

368 kips (1637 kN) |

393 kips (1748 kN) |

16.7 lbs/ft (24.8 kg/m) |

2-3/4” (70 mm) |

R61-20 |

| #24 – 3” – 2-3/4 (76 mm) * |

6.82 in2 (4400 mm2) |

682 kips (3034 kN) |

512 kips (2277 kN) |

546 kips (2429 kN) |

24.0 lbs/ft (35.8 kg/m) |

3-3/16” (81 mm) |

R61-24 |

| #28 – 3-1/2” – 2-3/4 (89 mm) * |

9.61 in2 (6200 mm2) |

961 kips (4274 kN) |

720 kips (3206 kN) |

769 kips (3421 kN) |

32.7 lbs/ft (48.6 kg/m) |

3-3/4” (95 mm) |

R61-28 |

| #32 – 4” – 2-3/4 (102 mm) * |

12.56 in2 (8103 mm2) |

1256 kips (5587 kN) |

942 kips (4190 kN) |

1004 kips (4466 kN) |

43.0 lbs/ft (64.0 kg/m) |

4-1/4” (108 mm) |

R61-32 |

* The #24 and #28 diameter bars are not covered under ASTM A615.

#32 Bar availability may be limited. Please contact Williams for specific lead times.

Structural Properties

| Minimum Yield |

Ultimate Tensile |

Typical Elongation in 8″ Bar |

|---|---|---|

| 75 KSI (517 MPa) |

100 KSI (689 MPa) |

7% – 9% |

Threads

Williams All-Thread Rebar has a cold rolled, continuous, rounded course thread form. Williams special thread (deformation) pattern projects ultra high relative rib area at 3 times that of conventional rebar. This provides for superior bond performance in concrete. Because of the high thread pitch and the full 360 degree concentric thread form, Williams All-Thread Rebar should only bent under special provisions using larger bend diameters than typical ACI minimums. As an alternative to bending, Williams recommends use of a steel plate or a threaded terminator disc to reduce development length. Threads are available in both right and left hand. Grades up to 100 are available upon request.

Sizes

All-Thread Rebar is available in 12 diameters from #6 through #32. Diameters #6 to #24 are available in continuous lengths up to 50-foot, larger diameters up to 40-foot.

Welding

Welding of All-Thread Rebar should be approached with caution since no specific provisions have been included to enhance its weldability. Refer to ANSI/AWS D1.4 for proper selections and procedures.

Grade 75 & Grade 80 All-Thread Rebar Accessories

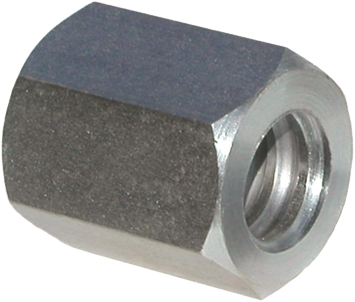

All Couplings and Hex/Collar Nuts exceed 100% of the bar’s published ultimate strength and couplings will meet ACI 318 Section 25.5.7.1 for mechanical rebar connections.

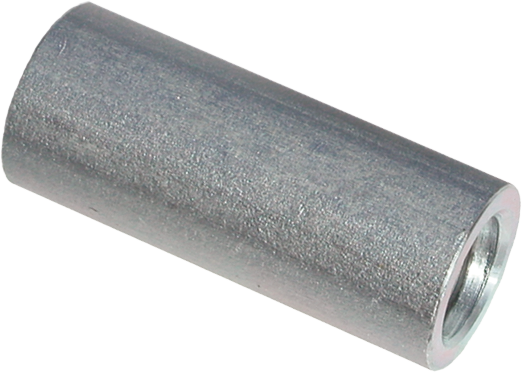

R62 Stop-Type Couplings

| Bar Diameter |

Outside Diameter |

Overall Length |

Part Number |

|---|---|---|---|

| #6 – 3/4” (19 mm) |

1-1/4” (32 mm) |

3-1/2” (89 mm) |

R62-06 |

| #7 – 7/8” (22 mm) |

1-3/8” (35 mm) |

4” (102 mm) |

R62-07 |

| #8 – 1” (25 mm) |

1-5/8” (41 mm) |

4-1/2” (114 mm) |

R62-08 |

| #9 – 1-1/8” (29 mm) |

1-7/8” (48 mm) |

5” (127 mm) |

R62-09 |

| #10 – 1-1/4” (32 mm) |

2” (51 mm) |

5-1/2” (140 mm) |

R62-10 |

| #11 – 1-3/8” (36 mm) |

2-1/4” (57 mm) |

6” (152 mm) |

R62-11 |

| #14 – 1-3/4” (43 mm) |

2-7/8” (73 mm) |

6” (152 mm) |

R62-14 |

| #18 – 2-1/4” (57 mm) |

3-1/2” (89 mm) |

7-1/8” (181 mm) |

R62-18 |

| #20 – 2-1/2” (64 mm) |

4” (102 mm) |

8” (203 mm) |

R62-20 |

| #24 – 3” (76 mm) |

5” (127 mm) |

9-3/4” (248 mm) |

R62-24 |

| #28 – 3-1/2” (89 mm) |

5-1/2” (140 mm) |

12” (305 mm) |

R62-28 |

| #32 – 4” (102 mm) |

5-3/4” (146 mm) |

12-1/2” (318 mm) |

R62-32 |

Couplings are available as tap thru upon request

R63 Hex Nuts / R64 Collar Nuts

Hex Nut Rounded Collar Nut

| Bar Diameter |

Across Flats |

Across Corners |

Thickness | Part Number |

|---|---|---|---|---|

| #6 – 3/4” (19 mm) |

1-1/4” (32 mm) |

1.44” (37 mm) |

1-1/8” (29 mm) |

R63-06 |

| #7 – 7/8” (22 mm) |

1-7/16” (37 mm) |

1.66” (42 mm) |

1-1/4” (32 mm) |

R63-07 |

| #8 – 1” (25 mm) |

1-5/8” (41 mm) |

1.88” (48 mm) |

1-3/8” (35 mm) |

R63-08 |

| #9 – 1-1/8” (29 mm) |

1-7/8” (48 mm) |

2.17” (55 mm) |

1-1/2” (38 mm) |

R63-09 |

| #10 – 1-1/4” (32 mm) |

2” (51 mm) |

2.31” (59 mm) |

2” (51 mm) |

R63-10 |

| #11 – 1-3/8” (36 mm) |

2-1/4” (57 mm) |

2.60” (66 mm) |

2-1/8” (54 mm) |

R63-11 |

| #14 – 1-3/4” (43 mm) |

2-3/4” (70 mm) |

3.18” (81 mm) |

3” (76 mm) |

R63-14 |

| #18 – 2-1/4” (57 mm) |

3-3/4” (95 mm) |

4.04” (103 mm) |

3-3/4” (95 mm) |

R63-18 |

| #20 – 2-1/2” (64 mm) |

4” (102 mm) |

4.62” (117 mm) |

3-3/4” (95 mm) |

R63-20 |

| #24 – 3” (76 mm) * |

4-1/2” (114 mm) |

OD 5” (127 mm) |

4-3/8” (111 mm) |

R64-24 |

| #28 – 3-1/2” (89 mm) * |

5-1/2” (140 mm) |

OD 6” (152 mm) |

5-1/2” (140 mm) |

R64-28 |

| #32 – 4” (102 mm) * |

5-3/4” (146 mm) |

OD 6.25” (159 mm) |

6” (152 mm) |

R64-32 |

*Rounded Collar Nut

R81 Spherical Washers

| Bar Diameter |

Thickness | Outside Dome |

Part Number |

|---|---|---|---|

| #6 – 3/4” (19 mm) |

35/64” (14 mm) |

2” (51 mm) |

R81-0675 |

| #7 – 7/8” (22 mm) |

39/64” (15 mm) |

2-1/4” (57 mm) |

R81-0775 |

| #8 – 1” (25 mm) |

5/8” (16 mm) |

2-1/2” (64 mm) |

R81-0875 |

| #9 – 1-1/8” (29 mm) |

3/4” (19 mm) |

2-3/4” (70 mm) |

R81-0975 |

| #10 – 1-1/4” (32 mm) |

53/64” (21 mm) |

3” (76 mm) |

R81-1075 |

| #11 – 1-3/8” (36 mm) |

29/32” (23 mm) |

3-1/4” (83 mm) |

R81-1175 |

| #14 – 1-3/4” (43 mm) |

1-7/64” (28 mm) |

3-3/4” (95 mm) |

R81-1475 |

| #18 – 2-1/4” (57 mm) |

1-13/32” (36 mm) |

5” (127 mm) |

R81-1875 |

| #20 – 2-1/2” (64 mm) |

1-1/2” (38 mm) |

5-1/4” (133 mm) |

R81-2075 |

| #24 – 3” (76 mm) |

1-7/8” (48 mm) |

6-1/2” (165 mm) |

R81-2475 |

| #28 – 3-1/2” (89 mm) |

1-1/2” (38 mm) |

7” (178 mm) |

R81-2875 |

Provides up to 5 ̊ angle when used with a dished plate.

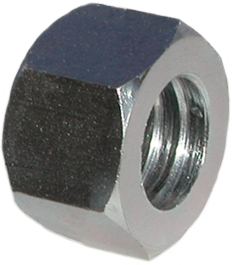

R63/R64-JN Jam Nuts

Hex Jam Nut Rounded Collar Jam Nut

Jam Nuts can not be substituted for full strength nuts. Larger diameters will be a rounded collar jam nut, with special order machined hex available.

| Bar Diameter |

Across Flats |

Across Corners |

Thickness | Part Number |

|---|---|---|---|---|

| #6 – 3/4” (19 mm) |

1-1/4” (32 mm) |

1.44” (37 mm) |

9/16” (14 mm) |

R63-06JN |

| #7 – 7/8” (22 mm) |

1-7/16” (37 mm) |

1.66” (42 mm) |

5/8” (16 mm) |

R63-07JN |

| #8 – 1” (25 mm) |

1-5/8” (41 mm) |

1.88” (48 mm) |

11/16” (17 mm) |

R63-08JN |

| #9 – 1-1/8” (29 mm) |

1-7/8” (48 mm) |

2.17” (55 mm) |

3/4” (19 mm) |

R63-09JN |

| #10 – 1-1/4” (32 mm) |

2” (51 mm) |

2.31” (59 mm) |

15/16” (24 mm) |

R63-10JN |

| #11 – 1-3/8” (36 mm) |

2-1/4” (57 mm) |

2.6” (66 mm) |

1” (25 mm) |

R63-11JN |

| #14 – 1-3/4” (43 mm) * |

2-5/8” (67 mm) |

OD 2.88” (73 mm) |

1-3/16” (30 mm) |

R64-14JN |

| #18 – 2-1/4” (57 mm) * |

3-1/4” (83 mm) |

OD 3.5” (89 mm) |

1-11/16” (43 mm) |

R64-18JN |

| #20 – 2-1/2” (64 mm) * |

3-3/4” (95 mm) |

OD 4” (102 mm) |

1-11/16” (43 mm) |

R64-20JN |

| #24 – 3” (76 mm) * |

4-1/2” (114 mm) |

OD 5” (127 mm) |

2” (51 mm) |

R64-24JN |

| #28 – 3-1/2” (89 mm) * |

5” (127 mm) |

OD 5.5” (140 mm) |

2-1/4” (57 mm) |

R64-28JN |

| #32 – 4” (102 mm) * |

5-3/4” (146 mm) |

OD 6.25” (159 mm) |

2-1/2” (64 mm) |

R64-32JN |

*Round Collar Jam Nut

R9F Hardened Washers

| Bar Diameter |

Outside Diameter |

Inside Diameter |

Thickness | Part Number |

|---|---|---|---|---|

| #6 – 3/4” (19 mm) |

1-3/4” (44 mm) |

15/16” (24 mm) |

5/32” (4 mm) |

R9F-07-436 |

| #7 – 7/8” (22 mm) |

2” (51 mm) |

1-1/16” (29 mm) |

5/32” (4 mm) |

R9F-08-436 |

| #8 – 1” (25 mm) |

2-1/4” (57 mm) |

1-3/16” (30 mm) |

5/32” (4 mm) |

R9F-09-436 |

| #9 – 1-1/8” (29 mm) |

2-1/4” (57 mm) |

1-3/16” (30 mm) |

5/32” (4 mm) |

R9F-09-436 |

| #10 – 1-1/4” (32 mm) |

2-1/2” (64 mm) |

1-3/8” (35 mm) |

5/32” (4 mm) |

R9F-10-436 |

| #11 – 1-3/8” (36 mm) |

3” (76 mm) |

1-5/8” (41 mm) |

5/32” (4 mm) |

R9F-12-436 |

| #14 – 1-3/4” (43 mm) |

3-3/8” (86 mm) |

1-7/8” (48 mm) |

7/32” (6 mm) |

R9F-14-436 |

| #18 – 2-1/4” (57 mm) |

4-1/2” (114 mm) |

2-5/8” (67 mm) |

9/32” (7 mm) |

R9F-20-436 |

| #20 – 2-1/2” (64 mm) |

5” (127 mm) |

2-7/8” (73 mm) |

9/32” (7 mm) |

R9F-22-436 |

| #24 – 3” (76 mm) |

6” (142 mm) |

3-3/8” (86 mm) |

9/32” (7 mm) |

R9F-26-436 |

| #28 – 3-1/2” (89 mm) |

7” (178 mm) |

3-7/8” (98 mm) |

9/32” (7 mm) |

R9F-30-436 |

| #32 – 4” (102 mm) |

7-3/4” (197 mm) |

4-3/8” (111 mm) |

5/16” (8 mm) |

R9F-34-436 |

R8M Beveled Washers

| Bar Diameter |

Degree of Bevel |

Outside Diameter |

Inside Diameter |

Maximum Thickness |

Minimum Thickness |

Part Number |

|---|---|---|---|---|---|---|

| #6 – 3/4” (19 mm) |

15° | 2-1/16″ (52 mm) |

1” (25 mm) |

3/4” (19 mm) |

1/4” (6 mm) |

R8M-08S |

| #7 – 7/8” (22 mm) |

15° | 2-1/16″ (52 mm) |

1” (25 mm) |

3/4” (19 mm) |

1/4” (6 mm) |

R8M-08S |

| #8 – 1” (25 mm) |

15° | 2-13/16” (71 mm) |

1-5/16” (33 mm) |

1” (25 mm) |

5/16” (8 mm) |

R8M-09S |

| #9 – 1-1/8” (29 mm) |

15° | 2-13/16” (71 mm) |

1-5/16” (33 mm) |

1” (25 mm) |

5/16” (8 mm) |

R8M-09S |

| #10 – 1-1/4” (32 mm) |

15° | 3-3/8” (86 mm) |

1-9/16” (40 mm) |

1-15/64” (44 mm) |

3/8” (10 mm) |

R8M-12S |

| #11 – 1-3/8” (36 mm) |

15° | 3-1/2” (89 mm) |

1-3/4” (44 mm) |

1-1/4” (32 mm) |

3/8” (10 mm) |

R8M-13S |

| #14 – 1-3/4” (43 mm) |

15° | 4-1/2” (114 mm) |

2-1/8” (54 mm) |

1-5/8” (41 mm) |

15/32” (12 mm) |

R8M-14S |

| #18 – 2-1/4” (57 mm) |

15° | 5” (127 mm) |

3” (76 mm) |

1-5/8” (41 mm) |

19/64” (7.5 mm) |

R8M-18 |

| #20 – 2-1/2” (64 mm) |

10° | 5-1/2” (140 mm) |

3” (76 mm) |

1-23/32” (44 mm) |

3/4” (19 mm) |

R8M-20 |

| #24 – 3” (76 mm) |

10° | 7” (178 mm) |

3-5/8” (92 mm) |

2” (51 mm) |

3/4” (19 mm) |

R8M-24 |

| #28 – 3-1/2” (89 mm) |

10° | 8” (203 mm) |

4-1/4” (108 mm) |

2-19/64” (58 mm) |

7/8” (22 mm) |

R8M-28 |

To achieve full strength of the system, beveled washers must be used in conjunction with a hardened washer.

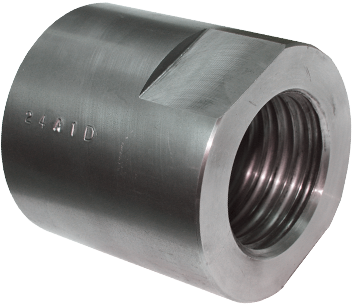

R64 Terminator

| Bar Desig. & Nominal Dia. |

Thickness | Terminator OD | Part Number |

|---|---|---|---|

| #6 – 3/4” (19 mm) |

1-1/4” (32 mm) |

1-7/8” (48 mm) |

R64-06-DN |

| #7 – 7/8” (22 mm) |

1-1/4” (32 mm) |

2-1/4” (57 mm) |

R64-07-DN |

| #8 – 1” (25 mm) |

1-3/8” (35 mm) |

2-1/2” (64 mm) |

R64-08-DN |

| #9 – 1-1/8” (29 mm) |

1-1/2” (38 mm) |

2-3/4” (70 mm) |

R64-09-DN |

| #10 – 1-1/4” (32 mm) |

2” (51 mm) |

3-1/8” (79 mm) |

R64-10-DN |

| #11 – 1-3/8” (36 mm) |

2-1/8” (54 mm) |

3-1/2” (89 mm) |

R64-11-DN |

| #14 – 1-3/4” (43 mm) |

2-1/2” (64 mm) |

4-1/8” (105 mm) |

R64-14-DN |

| #18 – 2-1/4” (57 mm) |

3-3/4” (95 mm) |

5-1/2” (140 mm) |

R64-18-DN |

| #20 – 2-1/2” (64 mm) |

3-3/4” (95 mm) |

6-1/8” (156 mm) |

R64-20-DN |

Williams threaded terminators offer an economical alternative to the conventional approach of a plate between two hex nuts. With only a single component, they are more efficient to install and reduce congestion around the reinforcement. Since they are used with Williams threaded bars, they can be easily adjusted to the desired location and require no specialized equipment to install unlike other terminator systems.

Williams terminators meet the requirements of ASTM A970 Class HA. The dimensions shown for bar sizes up to #11 (1-3/8”) exceed the requirements of ACI 318-19 Section 25.4.4, so can be used as headed reinforcement to reduce development length of a Williams threaded bar without the need for 90 degree bends or 180 degree hooks. Additionally, the nominal pullout strength of Williams terminators in 3000 psi concrete exceeds the specified tensile strength of the bar per ACI 318-19 Chapter 17. Other failure modes such as concrete breakout and side face blowout should be analyzed by the Engineer of Record.

For larger quantities, contact your Williams Representative to evaluate the cost saving design advantages of higher strength concrete.