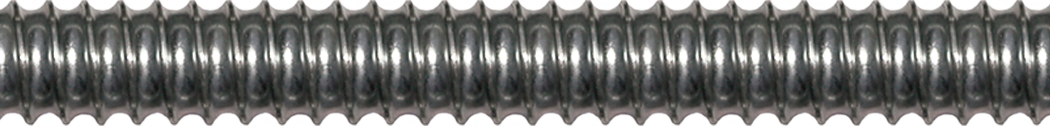

High Tensile Coil Threaded Rods

ASTM A108 Grade C1045 High Tensile Coil Threaded Tie Rods

| Bar Diameter & Pitch |

Minimum Net Area Thru Threads |

Minimum Ultimate Strength |

Minimum Yield Strength |

Part Number |

|---|---|---|---|---|

| 3/8” – 8 (19.5 mm) |

0.08 in2 (50 mm2) |

9.3 kips (41 kN) |

7.1 kips (32 kN) |

B7S-03 |

| 1/2” – 6 (13 mm) |

0.14 in2 (91 mm2) |

17 kips (75 kN) |

13 kips (58 kN) |

B7S-04 |

| 5/8” – 4-1/2 (16 mm) |

0.22 in2 (143 mm2) |

27 kips (118 kN) |

20 kips (90 kN) |

B7S-05 |

| 3/4” – 4-1/2 (19 mm) |

0.33 in2 (215 mm2 |

40 kips (178 kN) |

31 kips (136 kN) |

B7S-06 |

| 7/8” – 4-1/2 (22 mm) |

0.46 in2 (296 mm2) |

55 kips (245 kN) |

42 kips (187 kN) |

B7S-07 |

| 1” – 3-1/2 (25 mm) |

0.59 in2 (381 mm2) |

71 kips (315 kN) |

54 kips (241 kN) |

B7S-08 |

| 1-1/8” – 3-1/2 (28 mm) |

0.74 in2 (477 mm2) |

78 kips (345 kN) |

60 kips (266 kN) |

B7S-09 |

| 1-1/4” – 3-1/2 (32 mm) |

0.97 in2 (625 mm2) |

102 kips (453 kN) |

79 kips (349 kN) |

B7S-10 |

| 1-1/2” – 3-1/2 (38 mm) |

1.47 in2 (951 mm2) |

155 kips (689 kN) |

119 kips (531 kN) |

B7S-12 |

Structural Properties

| Diameter Range |

Yield Stress |

Ultimate Stress |

Elongation in 2″ bar diameter |

Reduction of Area |

|---|---|---|---|---|

| 3/8″ to 1″ (13 to 25 mm) |

92 KSI (634 MPa) |

120 KSI (827 MPa) |

11% | 20% min |

| 1-1/8″ and up (29 mm) |

81 KSI 558 MPa) |

105 KSI 723 MPa) |

11% | 20% min |

Meets strengths of ASTM A325

ASTM A108 Grade C1018 Mild Steel Coil Threaded Tie Rods

| Bar Diameter & Pitch |

Minimum Net Area Thru Threads |

Minimum Ultimate Strength |

Minimum Yield Strength |

Part Number |

|---|---|---|---|---|

| 3/8” – 8 (9.5 mm) |

0.08 in2 (50 mm2) |

5.4 kips (24 kN) |

4.7 kips (21 kN) |

B7G-03 |

| 1/2” – 6 (13 mm) |

0.14 in2 (91 mm2) |

9.9 kips (44 kN) |

8.5 kips (38 kN) |

B7G-04 |

| 5/8” – 4-1/2 (16 mm) |

0.22 in2 (143 mm2) |

16 kips (69 kN) |

13 kips (59 kN) |

B7G-05 |

| 3/4” – 4-1/2 (19 mm) |

0.33 in2 (215 mm2 |

23 kips (104 kN) |

20 kips (89 kN) |

B7G-06 |

| 7/8” – 4-1/2 (22 mm) |

0.46 in2 (296 mm2) |

32 kips (143 kN) |

28 kips (122 kN) |

B7G-07 |

| 1” – 3-1/2 (25 mm) |

0.59 in2 (381 mm2) |

41 kips (184 kN) |

35 kips (158 kN) |

B7G-08 |

| 1-1/8” – 3-1/2 (28 mm) |

0.74 in2 (477 mm2) |

52 kips (230 kN) |

44 kips (197 kN) |

B7G-09 |

| 1-1/4” – 3-1/2 (32 mm) |

0.97 in2 (625 mm2) |

68 kips (302 kN) |

58 kips (259 kN) |

B7G-10 |

| 1-1/2” – 3-1/2 (38 mm) |

1.47 in2 (951 mm2) |

103 kips (459 kN) |

88 kips (393 kN) |

B7G-12 |

Williams High Tensile Coil Tie Rods are available in all diameters shown, with lengths from 3” to 20’-0”. They are available all-threaded, thread one end, or threaded both ends. Short length tie rods threaded both ends under 2’-0” are usually crimped to prevent rotation in the concrete during removal of the Shebolt. Ties threaded each end allow easy spot-checking of the connection, to insure proper engagement.

Accessories

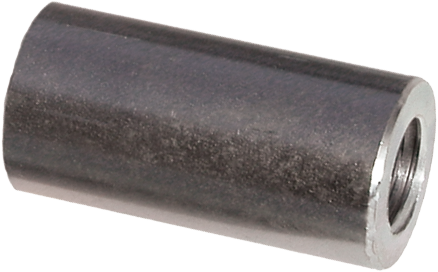

C2TC Stop-Type Couplings & C2DC Flange Couplings

| Bar Diameter |

Outside Diameter |

Overall Length |

Stop-Type Part Number |

Flange Coupling | |

|---|---|---|---|---|---|

| Flange Size | Part Number | ||||

| 3/8” (9.5 mm) |

3/4” (19 mm) |

1-1/2” (38 mm) |

C2T-03C | 2” x 2” (51 x 51 mm) |

C2D-03C |

| 1/2” (13 mm) |

3/4” (19 mm) |

1-1/2” (38 mm) |

C2T-04C | 2” x 2” (51 x 51 mm) |

C2D-04C |

| 5/8” (16 mm) |

1” (25 mm) |

1-3/4” (45 mm) |

C2T-05C | 2” x 2” (51 x 51 mm) |

C2D-05C |

| 3/4” (19 mm) |

1-1/8” (29 mm) |

2” (51 mm) |

C2T-06C | 2” x 2” (51 x 51 mm) |

C2D-06C |

| 7/8” (22 mm) |

1-1/4” (32 mm) |

2-1/4” (57 mm) |

C2T-07C | 3” x 3” (76 x 76 mm) |

C2D-07C |

| 1” (25 mm) |

1-1/2” (38 mm) |

3” (76 mm) |

C2T-08C | 3” x 3” (76 x 76 mm) |

C2D-08C |

| 1-1/8” (29 mm) |

1-5/8” (41 mm) |

3-1/2” (89 mm) |

C2T-09C | 3” x 3” (76 x 76 mm) |

C2D-09C |

| 1-1/4” (32 mm) |

1-7/8” (48 mm) |

3-3/4” (95 mm) |

C2T-10C | 3” x 3” (76 x 76 mm) |

C2D-10C |

| 1-1/2” (38 mm) |

2-1/4” (57 mm) |

5” (127 mm) |

C2T-12C | 3” x 3” (76 x 76 mm) |

C2D-12C |

H1FC Heavy Duty Hex Nuts

| Bar Diameter |

Across Flats |

Across Corners |

Thickness | Part Number |

|---|---|---|---|---|

| 3/8” (9.5 mm) |

11/16” (18 mm) |

0.8” (20 mm) |

23/64” (9 mm) |

H1F-03C |

| 1/2” (13 mm) |

7/8” (22 mm) |

1.0” (26 mm) |

31/64” (12 mm) |

H1F-04C |

| 5/8” (16 mm) |

1-1/16” (27 mm) |

1.2” (31 mm) |

39/64” (16 mm) |

H1F-05C |

| 3/4” (19 mm) |

1-1/4” (32 mm) |

1.4” (37 mm) |

47/64” (19 mm) |

H1F-06C |

| 7/8” (22 mm) |

1-7/16” (37 mm) |

1.7” (42 mm) |

55/64” (22 mm) |

H1F-07C |

| 1” (25 mm) |

1-5/8” (41 mm) |

1.9” (48 mm) |

63/64” (25 mm) |

H1F-08C |

| 1-1/8” (29 mm) |

1-13/16” (46 mm) |

2.1” (53 mm) |

1-7/64” (28 mm) |

H1F-09C |

| 1-1/4” (32 mm) |

2” (51 mm) |

2.3” (59 mm) |

1-7/32” (31 mm) |

H1F-10C |

| 1-1/2” (38 mm) |

2-3/8” (60 mm) |

2.7” (70 mm) |

1-15/32” (37 mm) |

H1F-12C |

R9F Hardened Washers

| Bar Diameter |

Outside Diameter |

Inside Diameter |

Thickness | Part Number |

|---|---|---|---|---|

| 3/8” (9.5 mm) |

1” (25 mm) |

7/16” (11 mm) |

5/64” (2 mm) |

R9F-03-436 |

| 1/2” (13 mm) |

1-1/16” (27 mm) |

17/32” (14 mm) |

9/64” (3.56 mm) |

R9F-04-436 |

| 5/8” (16 mm) |

1-5/16” (33 mm) |

11/16” (17 mm) |

9/64” (3.6 mm) |

R9F-05-436 |

| 3/4” (19 mm) |

1-7/16” (37 mm) |

13/16” (21 mm) |

9/64” (3.6 mm) |

R9F-06-436 |

| 7/8” (22 mm) |

1-3/4” (45 mm) |

15/16” (24 mm) |

5/32” (4 mm) |

R9F-07-436 |

| 1” (25 mm) |

2” (51 mm) |

1-1/16” (29 mm) |

5/32” (4 mm) |

R9F-08-436 |

| 1-1/8” (29 mm) |

2-1/4” (57 mm) |

1-3/16” (30 mm) |

5/32” (4 mm) |

R9F-09-436 |

| 1-1/4” (32 mm) |

2-1/2” (64 mm) |

1-3/8” (35 mm) |

5/32” (4 mm) |

R9F-10-436 |

| 1-1/2” (38 mm) |

3” (76 mm) |

1-5/8” (41 mm) |

5/32” (4 mm) |

R9F-12-436 |

R8M Beveled Washers

| Bar Diameter |

Outside Diameter |

Inside Diameter |

Thickness | Part Number |

|---|---|---|---|---|

| 3/8” (9.5 mm) |

1” (25 mm) |

7/16” (11 mm) |

5/64” (2 mm) |

R9F-03-436 |

| 1/2” (13 mm) |

1-1/16” (27 mm) |

9/16” (14 mm) |

9/64” (3.56 mm) |

R9F-04-436 |

| 5/8” (16 mm) |

1-3/4” (45 mm) |

11/16” (17 mm) |

9/64” (3.6 mm) |

R9F-05-436 |

| 3/4” (19 mm) |

1-15/32” (37 mm) |

13/16” (21 mm) |

9/64” (3.6 mm) |

R9F-06-436 |

| 7/8” (22 mm) |

1-3/4” (45 mm) |

15/16” (24 mm) |

5/32” (4 mm) |

R9F-07-436 |

| 1” (25 mm) |

2” (51 mm) |

1-1/8” (29 mm) |

5/32” (4 mm) |

R9F-08-436 |

| 1-1/8” (29 mm) |

2-1/4” (57 mm) |

1-1/4” (32 mm) |

5/32” (4 mm) |

R9F-09-436 |

| 1-1/4” (32 mm) |

2-1/2” (64 mm) |

1-3/8” (35 mm) |

5/32” (4 mm) |

R9F-10-436 |

| 1-1/2” (38 mm) |

3” (76 mm) |

1-5/8” (41 mm) |

5/32” (4 mm) |

R9F-12-436 |

To achieve full strength of the nut, beveled washers must be used in conjunction with a hardened washer.